Effluent Systems & Water Recycling Systems

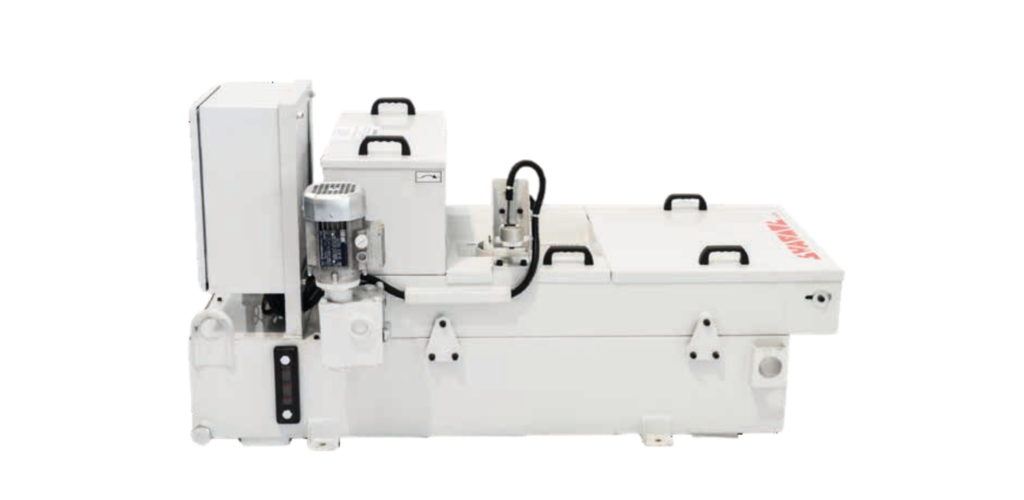

Paper band filters are a type of filtration system that is specifically designed to remove contaminants from the effluent discharged from vibratory finishing machines. They are manufactured in various sizes to suit a corresponding discharge rate, and they can be made from either carbon or stainless steel.

Process Water Recycling systems enable the treatment and reuse of wastewater generated in the process from single machine to multiple lines with different capacities. With high-speed centrifuge and gradual treatment, wastewater is purified from particles and unwanted substances and recycled to the system.

Water Recycling System

Paper Band Filters

| Model LPM | PBMF / PBF 50 | PBMF / PBF 65 | PBMF / PBF 100 | PBMF / PBF 150 | PBMF / PBF 200 | PBMF / PBF 300 | PBMF / PBF 400 |

|---|---|---|---|---|---|---|---|

| LT | 1300 | 1400 | 1800 | 1800 | 2200 | 2500 | 2200 |

| W | 550 | 800 | 800 | 1000 | 1000 | 1100 | 1500 |

The paper band filter works by continuously trapping contaminants on a filter paper. The filter paper is supported by a chain mesh belt, and it is automatically indexed when the solid content level rises to a certain point. This allows for continuous filtration without the need for manual intervention.

Metalworking

Paper band filters are used to remove metal chips and other contaminants from the effluent discharged from grinding machines and other metalworking equipment.

Plastics

Paper band filters are used to remove plastic shavings and other contaminants from the effluent discharged from injection moulding machines and other plastics processing equipment.

Foundry

Paper band filters are used to remove sand and other contaminants from the effluent discharged from casting machines and other foundry equipment.

Excellent filtration efficiency

Paper band filters can remove contaminants down to an exceptionally fine level, typically 10-50 microns.

Continuous

filtration

Paper band filters can operate continuously without the need for manual intervention.

Compact

design

Paper band filters are relatively compact, which makes them ideal for use in tight spaces.

Durable

construction

Paper band filters are made from high-quality materials, making them durable and reliable.

Filter Rolls

Filter rolls are available in a variety of micron ratings, including 10, 20, 45, and 50 microns. The micron rating of the filter roll determines the size of the contaminants that can be removed, and also the lower the micron, the longer the saturation period.

Full Recirculating Systems

Benefits:

- Significant reduction in water consumption

- Reduced chemical usage.

- Environmental protection by preventing pollution.

- Recycling of valuable ores when processing precious stones, gold, or jewellery

The system works in neutral waters (pH between 6.5-9.5).

Processes performed in the system:

- Flocculation

- Filtration

- Defoaming

| Machine Type | Unit | ARS25 B0 | ARS25 B60 | ARS25 MN500 | ARS25 MN1000 | ARS140 B1000 |

|---|---|---|---|---|---|---|

| Capacity | Liter/Hour | 300 | 300 | 300 | 300 | 1200 |

| Clean Water Tank Capacity | Liter | - | 30 | 270 | 556 | 482 |

| Waste Water Tank Capacity | Liter | - | 30 | 135 | 260 | 338 |

| Total Tank Capacity | Liter | - | 120 | 405 | 816 | 820 |

| Sludge Container Capacity | kg | 2,5 | 2,5 | 2,5 | 2,5 | 22 |

| Max. Clean Water Outlet Pressure | bar | 0,5 | 0,5 | 0,5 | 0,5 | 0,3 |

| Separation Factor | g | 1800 | 1800 | 1800 | 1800 | 2010 |

| Centrifugal Speed | rpm | 4100 | 4100 | 4100 | 4100 | 2750 |

| Motor Power | kW | 1,5 | 1,5 | 1,5 | 1,5 | 5 |

| Total Power | kW | 1,5 | 2 | 1,5 | 1,5 | 5,5 |

| Measurements | mm | 702x413x780 | 680x800x800 | 1560x760x1392 | 2060x1080x1392 | 2120x1275x1695 |

| Total Weight | kg | 115 | 160 | 290 | 335 | 620 |

| Control Unit | - | Semiautomatic | Semiautomatic | Semiautomatic | Semiautomatic | Semiautomatic |

| Chemical Dosing | - | - | Optional | Standard | Standard | Standard |

| Filtering | - | Centrifugal Filter | Centrifugal Filter | Centrifugal Filter | Centrifugal Filter | Centrifugal Filter |

| Defoaming | - | Optional | Optional | Optional | Optional | Optional |

| Water Recycling Rate | % | 95 | 95 | 95 | 95 | 95 |

WATCH OUR VIDEO ON THE BAND FILTER

Sharmic: Your Partner in Surface Finishing Excellence

Contact us today to discuss how our vibratory finishing machines can revolutionise your surface finishing capabilities.