Vibratory Sieves and Separators

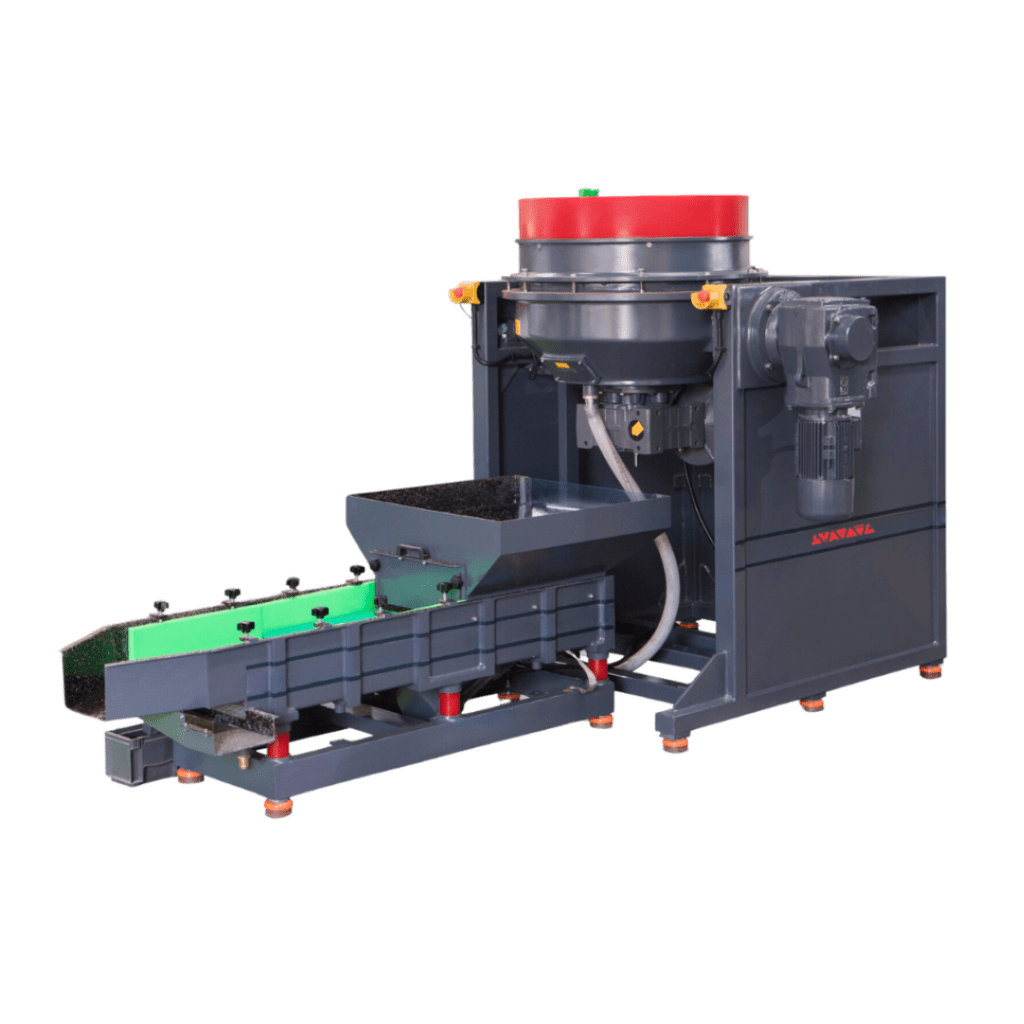

Vibratory separators are machines that use vibration to separate materials based on their size and density. They are often used in surface finishing processes to separate finishing media from parts, or to separate different sizes of parts. They can be used separately from the vibratory finishing machines and loaded manually, or they can be part of a system, like the centrifuge systems, where the machine tilts and deposits the media chips and parts for separation.

Separating finishing media from parts

After a batch of components have been finished, the finishing media is separated from the parts using a vibratory sieve. This separates the two for an automatic operation.

Separating different sizes of parts

Vibratory sieves can also be used to separate different sizes of parts. This is often done in processes such as deburring and polishing, where smaller components separate from larger components.

Benefits of using vibratory sieves or separators in surface finishing processes:

Vibratory sieves can separate materials quickly and efficiently. This is important in surface finishing processes where it is necessary to process large batches of parts.

Sharmic machine owners enjoy the benefits of our diverse range of material capacities, automated solutions, and integrated drying and wastewater treatment systems. Our commitment to innovation extends to our technological testing laboratories, where we continuously develop and refine our process solutions to meet the evolving needs of our customers.

With a vast database of thousands of proven solutions, we carefully select and tailor our offerings to address the unique surface treatment requirements of each customer. Our dedicated team of experts collaborates closely with you to understand your specific needs and provide the optimal solution for your application.

At Sharmic, we are committed to providing our customers with exceptional value and long-lasting service. Our test lab offers comprehensive sample process studies to determine the most suitable machine systems, surface finishing abrasives, and processes for your production needs.

Vibratory separators are available in a variety of sizes and capacities, VE14, VE50 and VE75.

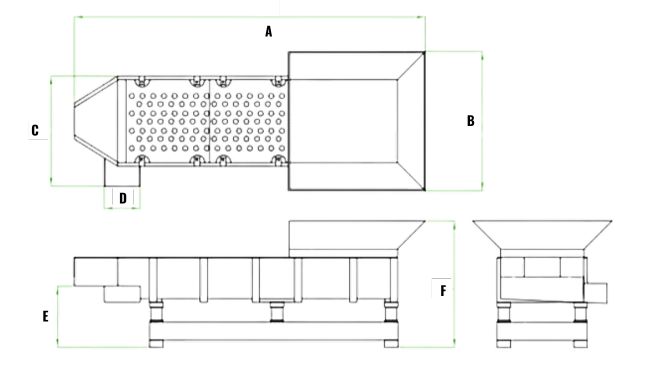

| Machine Type | A | B | C | D | E | F | Total Volume Lt. | Weight kg. | Motor Speed d/d | Motor Power kW | Voltage |

|---|---|---|---|---|---|---|---|---|---|---|---|

| VE50 | 1290 | 500 | 610 | 194 | 390 | 655 | 50 | 190 | 1500 | 0.75 | 380/50 |

| VE75 | 1940 | 765 | 610 | 194 | 405 | 765 | 75 | 242 | 1500 | 0.75 | 380/50 |

| VE100 | 2175 | 950 | 980 | 170 | 869 | 1285 | 100 | 385 | 1500 | 0.75 | 380/50 |

If you are looking for a reliable and efficient way to separate materials in your surface finishing process, a vibratory sieve is a good option to consider.

Sharmic: Your Partner in Surface Finishing Excellence

Contact us today to discuss how our vibratory finishing machines can revolutionise your surface finishing capabilities.