Why Correct Media Type, Shape, and Size Are Essential in Vibratory Finishing

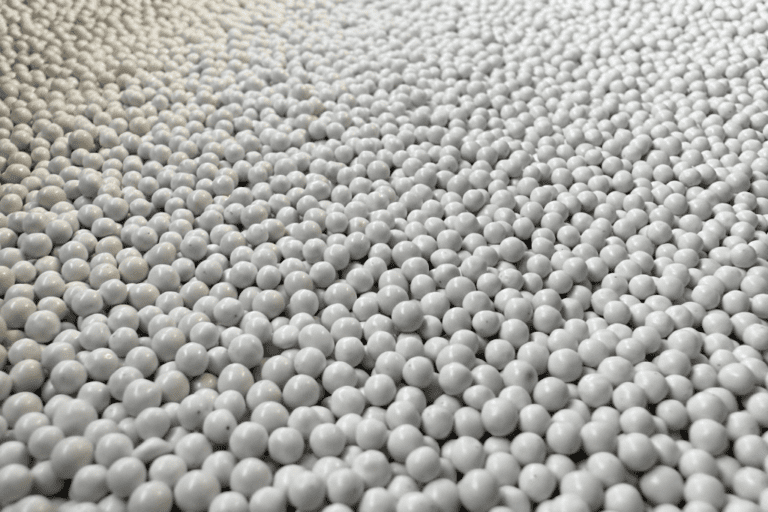

TXC 3mm porcelain spheres, great for polishing

In the world of vibratory finishing, success depends on more than just the machine — it depends on selecting the correct media type, shape, and size for the application. At Sharmic Engineering, we work with customers across industries to optimise their finishing processes, ensuring that every component achieves the desired result efficiently, safely, and without unnecessary delays.

The Role of Media in Vibratory Surface Finishing

Whether you are working with vibratory bowl machines, vibratory troughs, or centrifugal finishing machines, the right media makes all the difference. The choice between plastic media, ceramic media, porcelain media, maizorb, or walnut shell will directly affect the outcome of critical processes such as:

- Deburring: Removing sharp edges, burrs, and flash from machined or cast parts.

- Polishing: Achieving smooth, high-gloss surfaces on metals, plastics, or composites.

- Surface preparation: Preparing components for coating, painting, or assembly by cleaning or lightly abrading the surface.

- Descaling or radiusing: Removing scale or rounding sharp edges for safety and aesthetics.

What Can Go Wrong with Poor Media Selection?

Choosing the wrong media type, shape, or size can introduce a range of production problems:

- Inconsistent finish: Too aggressive media can damage delicate components, while less coarse media fails to meet finish requirements.

- Reduced process efficiency: Improper media slows down vibratory or centrifugal finishing cycles, reducing throughput and increasing operational costs.

- Increased media and compound consumption: Incorrect selections waste not only media but also valuable liquid, paste, or powder compounds.

- Lodgement issues: One of the most common challenges we see in vibratory finishing — using media of the wrong shape or size leads to it getting lodged in holes, slots, or recesses. This results in manual removal, process interruptions, and delivery delays.

TC1 Ceramic triangular shaped media, angle cut – great for deburring/brightening

How We Help: Tailored Sample Trials

At Sharmic Engineering, we understand that the best way to avoid these issues is to develop a tailored finishing setup for each customer. We invite you to send us your sample components for trial processing in our in-house subcontract finishing division.

Our expert team will:

- Assess your component’s material, design, and surface requirements.

- Run tests across different media types (e.g., plastic, ceramic, porcelain), shapes (triangles, cones, cylinders), and sizes to determine the best combination for your vibratory finishing or centrifugal finishing application.

- Optimise the use of compounds to support cleaning, polishing, or surface preparation as needed.

- Provide you with a proven, tested process setup designed to deliver excellent results with no risk of media lodgement or unnecessary delays.

Why It Matters

A well-optimised vibratory finishing process does more than save time — it improves product quality, reduces rework, lowers media and compound costs, and helps you meet delivery deadlines. By partnering with Sharmic Engineering, you gain access to decades of experience, and a team committed to fine-tuning your vibratory surface finishing setup for the best possible results.

Contact Us Today

If you are uncertain which media type, shape, or size best suits your components, or if you would like to arrange a sample trial to develop a customised vibratory or centrifugal finishing process, please get in touch with Sharmic Engineering today. We are here to help you improve finishing performance, avoid production delays, and achieve consistently high-quality outcomes, no matter your industry or application.

Stainless steel pins, great for polishing