What Do Our Machines Do?

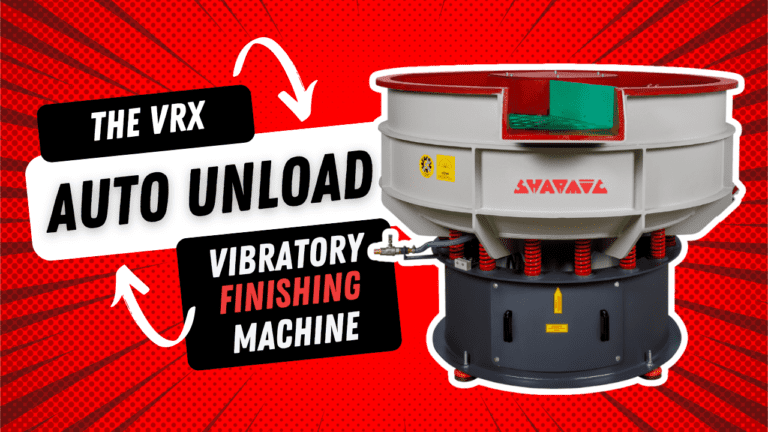

VRX Circular Type Machine with Automatic Unloading

What is a Vibratory Finishing Machine?

A vibratory finishing machine is used to improve the surface of metal or plastic components. It works by shaking or vibrating a container filled with parts, abrasive media and a finishing compound. The constant movement causes the parts to rub against the media, which helps to remove sharp edges, smooth surfaces or polish the components.

This process is commonly used in industries such as automotive, aerospace and engineering. It is ideal for deburring, cleaning and preparing surfaces before further treatments like painting or plating. The machine can process many parts at once, making it a cost-effective solution for high-volume production.

What is a Vibratory Trough Machine?

A vibratory trough machine works in a similar way to a vibratory finishing machine, but it is shaped differently. Instead of a round bowl, it has a long, rectangular container or ‘trough’. This makes it suitable for larger or longer parts that would not fit in a circular machine.

The trough vibrates, causing the parts and media inside to move against each other. This action removes burrs, polishes surfaces or cleans components. Vibratory troughs are commonly used for items like metal bars, tubes, castings or delicate items that require more careful handling. They are also useful when separating parts is important, as dividers can be placed within the trough.

What is a Centrifugal Disc Finishing Machine?

A centrifugal disc finishing machine is a high-energy finishing system. It uses a spinning disc at the base of a container to create intense movement of parts and media. The spinning action generates high speed and pressure, making it much faster than standard vibratory machines.

These machines are ideal for small to medium-sized parts that need quick processing. They are especially good for fine polishing, precision deburring or producing a high-quality surface finish. Because of the speed and force involved, the machine delivers efficient results in a short amount of time, making it popular in industries with tight production schedules.

Bank of Three Centrifugal Finishing Machines

What is a Tumbler?

A tumbler is a simple finishing machine used to smooth, clean or polish parts. It usually consists of a barrel or drum that rotates slowly, causing the parts inside to tumble over one another along with media and a compound. As the parts move, they gradually become smoother or cleaner through constant contact with the media.

Tumblers are often used for small parts and are popular in jewellery making, metalworking and craft industries. Although the process can be slower than other types of machines, it is gentle and effective. Tumblers can be powered by electricity or used manually, depending on the application.

What is a Rotary Barrel?

A rotary barrel is a type of finishing machine that uses rotation to treat the surface of parts. The machine contains a barrel that turns around its axis. Inside the barrel are the components, media and finishing compound. As it rotates, the contents tumble together, allowing the media to grind against the parts.

Rotary barrels are effective for deburring, polishing and surface cleaning. They are often used for harder metals or parts that require a thorough finish. The process is usually slower than high-energy systems, but it produces a consistent and reliable result. These machines are suitable for both small batches and larger quantities, depending on the size of the barrel.

VA75 Single Phase Tumbler – 21L