Choosing the Right Media for Your Finishing Process: Plastic, Ceramic, Porcelain and More

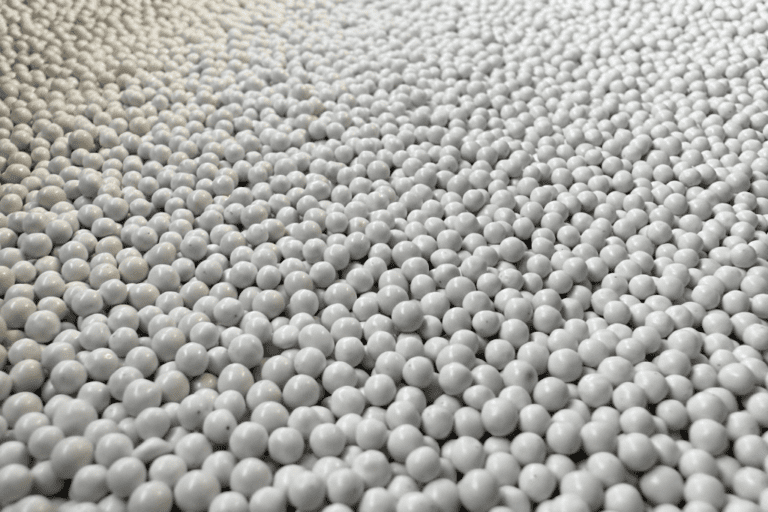

TCX porcelain media for polishing

In any vibratory surface finishing operation, selecting the correct media is absolutely critical. The type, shape, and size of media you use will directly affect the final finish on your components, as well as the efficiency, consistency, and cost-effectiveness of the process. At Sharmic Engineering, we offer expert guidance and supply a full range of vibratory media tailored to suit every type of component and finishing requirement.

This blog outlines the most common types of finishing media available, their ideal uses, and how to choose the right solution for your business.

Why Finishing Media Matters

Media is the working tool of any vibratory finishing process. It is the abrasive or polishing material that physically interacts with your parts inside the machine. As the vibratory bowl or trough oscillates, the media grinds against the surface of each component, helping to:

- Deburr rough edges

- Smooth surfaces

- Remove oxides or scale

- Achieve a polished, uniform finish

- Clean and dry components without damage

Choosing the wrong media can result in poor finishes, increased cycle times, and even damage to your parts, especially if they are delicate or geometrically complex.

Types of Vibratory Finishing Media

Plastic media is typically made from polyester resin and various abrasives. It is lightweight and cuts less aggressively than ceramic media, making it ideal for:

- Soft metals like aluminium, brass, or zinc

- Parts that require smooth, controlled edge-breaking

- Components with fine details or delicate features

Advantages: Produces a smooth finish without impinging the surface. Less likely to cause part deformation.

Best for: Aerospace, automotive trim, electronics housings, decorative components

Ceramic media is made from fired clay and mineral abrasives and is known for its hardness and long service life. It offers aggressive cutting action and is ideal for:

- Ferrous metals such as steel, stainless steel, and cast iron

- Removing heavy burrs and sharp edges

- Descaling heat-treated parts

Advantages: Durable, consistent performance in harsh applications

Best for: General engineering, forging, casting, machining workshops

Porcelain is a non-abrasive media used primarily for polishing. It is highly effective in producing bright, reflective finishes without cutting into the surface.

Advantages: Non-abrasive, excellent for high lustre finishing and aesthetic parts

Best for: Jewellery, stainless steel components, decorative finishes

These biodegradable, organic options are used for delicate cleaning, drying and light polishing. Walnut shell and maizorb (corn cob) are soft enough not to damage surface detail or change part geometry.

Advantages: Eco-friendly, non-toxic, ideal for sensitive applications

Best for: Drying of components post-process, electronics, aerospace, and restoration work

Ceramic wedge-shaped media for deburring, edge radiusing, and surface finishing applications.

To select the correct media for your application, consider the following:

- Material of your parts (aluminium vs steel vs plastic)

- Size and geometry of the parts (threads, cavities, recesses)

- Finish required (matte, satin, polished)

- Cycle time targets

- Regulatory or environmental standards

- Machine type (bowl, trough, centrifugal, barrel)

Size, Shape and Wear Rate

Media comes in a wide variety of shapes including cones, pyramids, cylinders, and tri-stars. Shape affects the flow of media around parts and access to detailed areas.

- Small media: Reaches fine details, but wears out faster

- Large media: More aggressive, better for flat surfaces

Wear rate also varies. Natural media must be replaced more frequently but is more sustainable.

Conclusion

The right vibratory finishing media ensures better results, faster processing, and lower total costs. At Sharmic Engineering, we supply high-quality plastic, ceramic, porcelain, and natural media and provide tailored advice for your finishing goals.

Visit: www.sharmic.co.uk

P67 Plastic Triangular Media