A Legacy of Finishing Solutions

Since 1975, Sharmic has delivered advanced vibratory finishing solutions, polishing industrial parts with a family-run approach. Therefore, our journey over three generations drives us to create new, sustainable technologies.

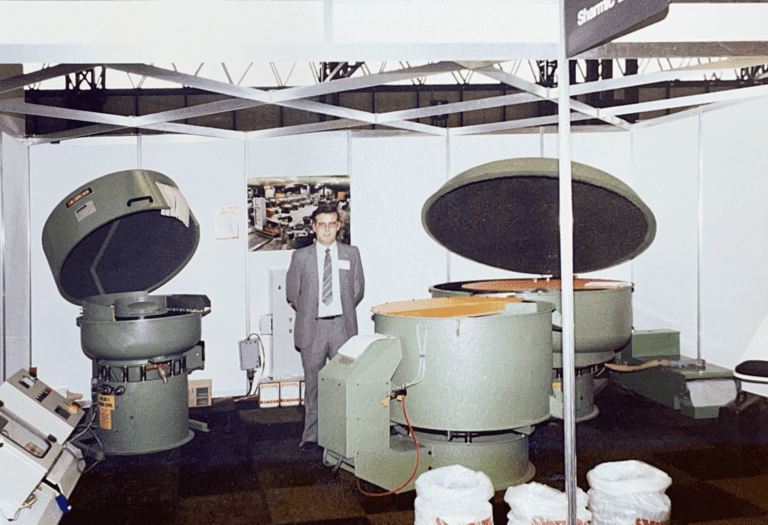

In August 1975, Brian Colwell launched Sharmic Engineering to provide affordable vibratory finishing solutions. As a result, the company quickly built a reputation for quality and innovation.

The name "Shar-Mic" blends Brian’s daughters’ names, Sharon and Michelle. Consequently, it reflects our family values and commitment to excellence.

In 1976, Sharmic became a limited company. This change created a safer business model, protecting owners from financial risks. Moreover, it strengthened our foundation for growth and better management.

In 2004, Sharmic bought CYTOBRI, a finishing company started by Cyril Clarke, Anthony Burcher, and Brian Colwell. Therefore, CYTOBRI became our subcontract division, offering top-quality vibratory finishing solutions.

This move expanded our services across industries. For example, we now finish parts for automotive and aerospace clients.

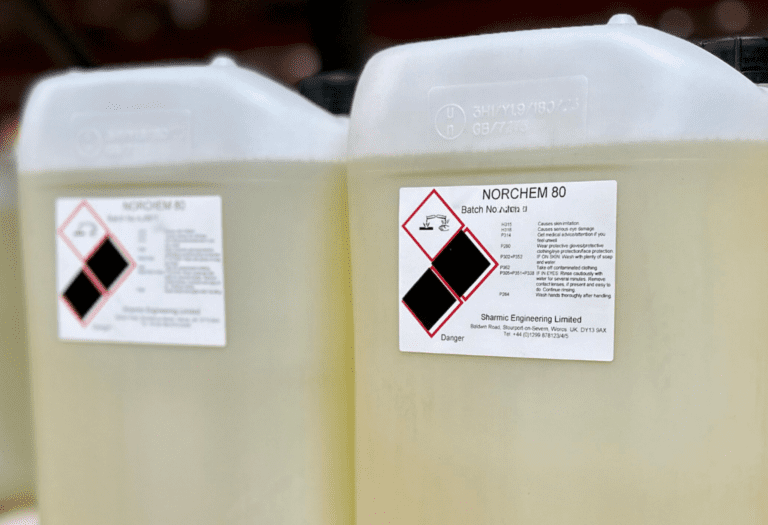

Sharmic acquired Norfinish Engineering in 2008. This added advanced surface finishing machines and liquid compounds to our offerings. As a result, we became a leading provider of vibratory finishing solutions in the UK.

In April 2018, Sharmic upgraded its roof with an EU grant. The new roof uses energy-saving materials and translucent panels. Consequently, it reduces energy use and brightens our workspace with natural light.

In 2021, Sharmic built a factory extension with a new equipment showroom. This space displays our vibratory finishing solutions.

Furthermore, our process lab offers free trials to customise solutions for customer parts, ensuring perfect results.

In 2023, Sharmic added solar panels to its roof. This step cut electricity costs and our carbon footprint. Therefore, it shows our commitment to eco-friendly vibratory finishing solutions.

In 2025, Sharmic added two electric vehicles to its fleet. Powered by our solar panels, they support sustainable operations.

Moreover, these vehicles complement our hybrid vehicle, reinforcing our focus on green vibratory finishing solutions.

Sharmic installed a high-speed, insulated roller shutter door in 2025. This upgrade improves security and saves energy. As a result, it creates a comfortable workplace while supporting sustainability.

Celebrating our 50 years golden anniversary we mark five decades of experience innovation and reliability in surface finishing. From our early beginnings to a trusted UK specialist we remain committed to delivering high quality surface finishing machines consumables and expert support for manufacturers across the UK.

Meet the Team

Brian Colwell

Managing Director

Sharon Edwards

General Manager

Garry Edwards

Technical Sales Director

Michelle Francis

Accounts Manager

James Turner

Technical Sales Manager

Reece Bennett

Area Sales & Marketing Manager