Discover the VRX Range: Automatic Unloading Vibratory Bowls Revolutionising Surface Finishing

In the fast-paced world of manufacturing, efficiency isn’t just a buzzword—it’s a necessity. Whether you’re tackling deburring, radiusing, polishing, edge breaking, degreasing, cleaning, or surface smoothing on ferrous and non-ferrous metals, plastics, ceramics, natural stones, glass, wood, or rubber products, the right equipment can make all the difference. Enter the VRX range of automatic unloading vibratory bowls from Sharmic—a significant change in vibratory finishing machinery that combines innovative automation with unmatched versatility.

At Sharmic, our VRX series handles everything from delicate small components to hefty industrial parts, ensuring your production line runs smoother, faster, and with less downtime. Ready to unleash the power of automated vibratory surface finishing? Let’s dive into why the VRX range is the ultimate solution for your surface treatment needs.

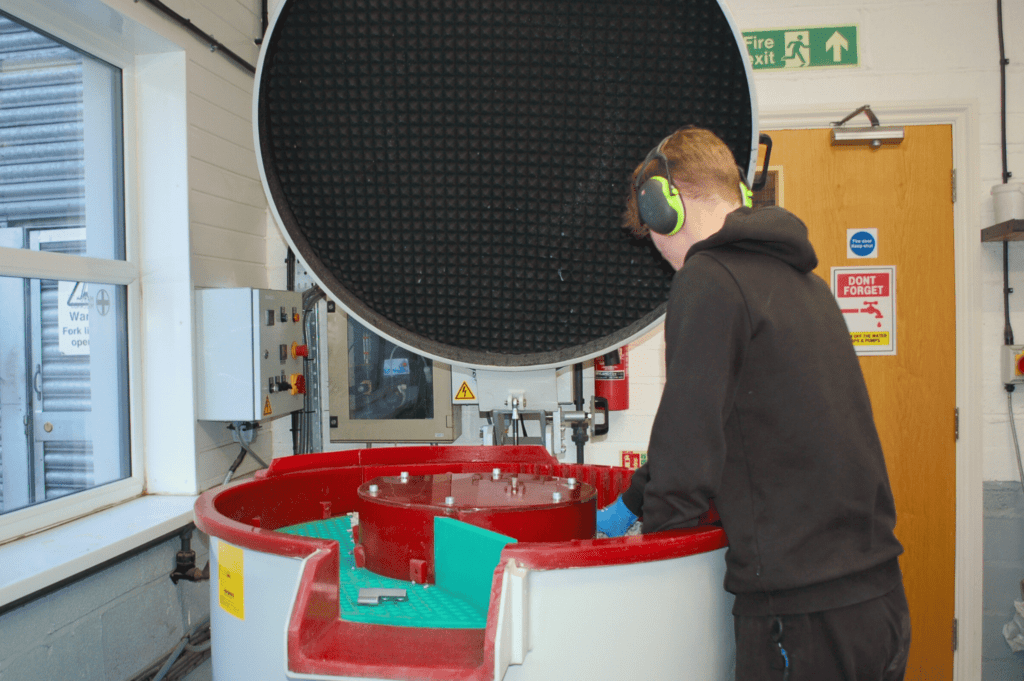

VRX 225 automatically unloading with the ramp in down position

What Makes Automatic Unloading Vibratory Bowls a Must-Have?

Traditional vibratory finishing machines often mean manual unloading—time-consuming, labour-intensive, and prone to errors. But with automatic unloading vibratory machinery like the VRX series, you get a seamless process that boosts productivity by 10-15%. These bowls use advanced pneumatic systems and quick-release mechanisms to discharge finished parts effortlessly, minimising handling and maximizing throughput.

Key advantages include:

– Reduced Labour Costs: No more manual sieving—parts unload automatically via optional pneumatic ramps.

– Enhanced Safety: Less operator intervention means fewer risks in high-volume environments.

– Consistent Quality: Uniform agitation and unloading prevent part damage, ensuring flawless finishes every time.

The VRX range excels in vibratory deburring and polishing applications, making it ideal for industries like automotive, aerospace, jewellery, and medical device manufacturing. With capacities from 118 litres (VRX125) to a robust 2400 Liters (VM3200), there’s a model tailored to your scale.

Standout Features of the Sharmic VRX Series

What sets the VRX range apart in the crowded field of vibratory finishing machines? It’s our unwavering commitment to innovation and quality. Each model in the series comes loaded with features designed for reliability and ease of use:

– Free Control Panels: Standard on all VRX models for intuitive operation and real-time monitoring.

– Quick Release Unload Screens: Swap screens in seconds for different part sizes, keeping your workflow uninterrupted.

– Automatic Greasing: Built-in lubrication systems extend machine life and reduce maintenance hassles.

– Pneumatic Unload Ramp (Optional): Effortlessly elevates for gravity-fed unloading, perfect for high-volume runs.

– Integrated Solutions: Pair with our drying systems and wastewater treatment for a complete, eco-friendly setup.

Take the flagship VRX 800 vibratory finishing machine, for instance. With an 800-litre capacity, it’s a powerhouse for medium-to-large batches, featuring a 6mm steel thickness for durability and an 11kW motor that delivers 1500 RPM for optimal agitation.

Aluminium components discharging into VRK drying machinery

VRX Range Specifications: Choose Your Perfect Fit

Selecting the right vibratory bowl machine starts with specs that match your operation. All models boast a 20-35mm PU (polyurethane) lining for noise reduction and part protection, with steel thicknesses scaled for heavy-duty performance.

Applications Across Industries: From Metals to Wood

The VRX range’s flexibility shines in diverse surface finishing applications. Deburr non-ferrous metal stampings for electronics? Check. Polish ceramic tiles for architectural use? Absolutely. Even clean and smooth wooden components for furniture makers—these bowls handle it all with gentle yet effective vibration.

Our team collaborate with you to test samples in our labs, dialling in the perfect abrasives and processes. The result? Tailored vibratory edge breaking solutions that cut cycle times and elevate finish quality.

Why Partner with Sharmic for Your Vibratory Finishing Needs?

Sharmic isn’t just a supplier—we’re your partner in surface finishing excellence. With decades of expertise, we offer:

– Comprehensive Testing: Free sample studies to optimise your setup.

– Global Support: Long-lasting service backed by a vast solution database.

– Sustainability Focus: Integrated wastewater systems for eco-conscious operations.

Customers rave about the “Sharmic difference”—that 10-15% efficiency boost translates to real ROI. Whether upgrading from manual systems or scaling up production, our automatic unloading vibratory bowls deliver.

Ready to Transform Your Surface Finishing Process?

Don’t let outdated equipment hold you back. Explore the full VRX range today and see how automatic unloading vibratory machinery can supercharge your operations. Contact Sharmic now at https://sharmic.co.uk/machines/automatic-unload-vibratory-machinery/ for a personalised consultation or visit our test lab to trial your parts. Your path to superior deburring, polishing, and beyond starts here—let’s make it happen.