How Vibratory Finishing Machines Can Save Your Company Money

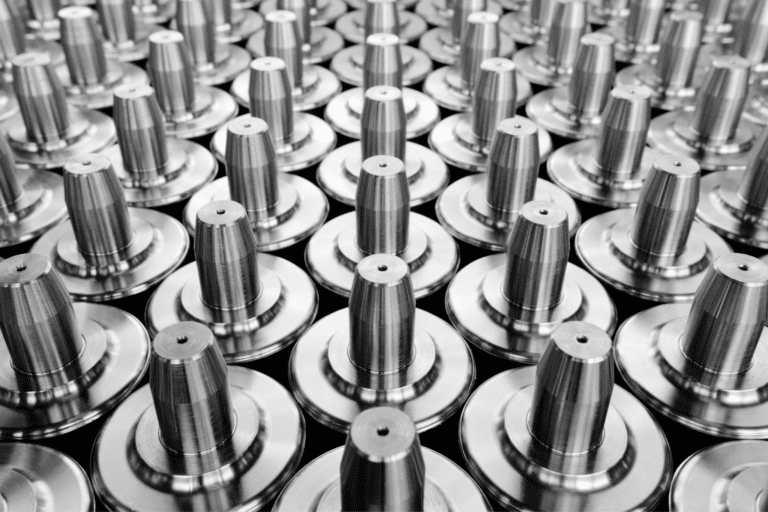

Stainless steel components

In today’s highly competitive business environment, companies must find ways to increase productivity and reduce costs without sacrificing quality. Vibratory finishing is a proven solution for businesses looking to save money in their manufacturing processes. At Sharmic Engineering, we offer cutting-edge vibratory finishing machines that not only streamline your production but also provide significant cost savings in various aspects of your operations. In this blog, we will explore how vibratory finishing can help your company reduce expenses and maximise efficiency.

Reducing Labour Costs

One of the most significant benefits of vibratory finishing machines is the reduction in labour costs. In traditional surface finishing methods, skilled operators are required to perform tasks such as deburring, polishing, and smoothing components. These manual processes can be time-consuming and labour-intensive, especially when processing large volumes of components.

With vibratory finishing systems, much of the manual labour is replaced with automation. Vibratory machines can run continuously without requiring constant operator attention, reducing the need for multiple workers. Operators can instead monitor the process from a distance, overseeing multiple machines at once, which reduces the overall workforce needed for surface finishing tasks. This allows businesses to allocate resources to other areas and ultimately reduces labour costs across the production line.

Reducing Equipment Waste

Another area where vibratory finishing machines help save money is by optimising the use of media and compounds. Unlike manual finishing methods, which often result in excessive wear on equipment, vibratory machines are designed to work efficiently. By selecting the right media and using it in a well-optimised system, businesses can minimise media waste, reducing the frequency of replenishment and lowering consumable costs.

Additionally, vibratory finishing machines are equipped with features that help extend the life of media, such as adjustable speeds and timers. These features ensure that media performs at its best for longer, resulting in fewer replacements and lower overall consumable costs.

Castings

Improving Production Efficiency

Vibratory finishing systems are incredibly efficient. With the ability to process large quantities of components at once, they significantly reduce production time. Traditional finishing methods often involve long cycles for each part, but vibratory finishing can handle large batches simultaneously, greatly increasing throughput. This enhanced productivity results in faster turnaround times, meaning more products can be processed in less time, which ultimately leads to higher output and revenue.

Moreover, the automated nature of vibratory finishing reduces downtime. Machines can run continuously, even overnight, without requiring operator intervention, maximising your production capacity. By reducing downtime and increasing efficiency, vibratory finishing machines help businesses meet demand while controlling costs.

Reducing Post-Processing Costs

Vibratory finishing is an all-in-one solution that can eliminate the need for multiple post-processing steps. Whether it’s deburring, polishing, or smoothing, the vibratory finishing machine handles everything in one cycle. This reduces the need for additional equipment or processes, saving you both time and money. Businesses can skip steps in the production line that would traditionally incur additional expenses.

Conclusion

Vibratory finishing machines are an investment that can pay for themselves in the long run by reducing labour costs, optimising media use, increasing productivity, and eliminating unnecessary post-processing steps. At Sharmic Engineering, we offer a variety of vibratory finishing solutions designed to help your business save money while maintaining high standards of quality. Investing in the right machinery and consumables can provide significant long-term savings and increased profitability.

Aluminium components