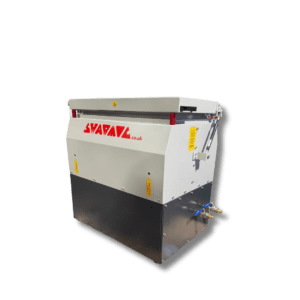

Trough Surface Finishing Machines

Our Vibratory Trough Surface Finishing Machines are the ideal solution for the surface finishing of heavy, large, long, or sensitive parts. Our machines offer unmatched versatility, enabling you to achieve a wide range of finishes, from deburring and polishing to radiusing and cleaning.

Ideal for heavy and long components

Our machines are ideal for the surface finishing of heavy and sensitive components, thanks to their robust construction and gentle handling capabilities. The process chamber is designed to minimise media loss and contamination, while the vibration-absorbing couplings protect sensitive components from damage.

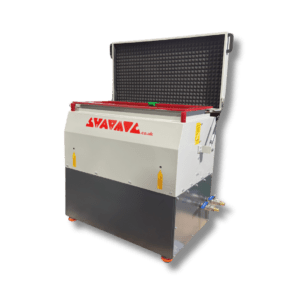

Adjustable and divided process chambers

The process chamber in the Sharmic Trough Surface Finishing Machines can be adjusted or divided into independent sections with fixed separators. This feature is especially useful for processing different types of components or using different process materials in each section.

Acoustic soundproofing covers

Optional acoustic soundproofing covers can be installed on our machines to reduce noise levels. This is ideal for use in manufacturing environments where noise is a concern.

Seamless operation and superior results

Sharmic Through Vibratory Surface Finishing Machines are equipped with a number of features that ensure seamless operation and superior results, including:

- Drive motors mounted under the machine: This design minimises vibration and noise, while providing optimal performance.

- Synchronous drive motors: These motors provide consistent and precise vibration, ensuring consistent results.

- Unique vibration-absorbing couplings: These couplings protect sensitive parts from damage and reduce vibration levels.

VTFM and VM Vibratory Finishing Machines Technical Data

Discover high-performance vibratory finishing machines for deburring, polishing, and surface treatment at www.sharmic.co.uk. Our VTFM and VM series offer reliable solutions with varying capacities and dimensions to suit your industrial needs. Tip: Select the appropriate PU thickness and motor power based on your material type for optimal results and longevity.

VTFM Series

| Model | Total Volume (L) | Length (mm) | Width (mm) | PU Thickness (mm) | Weight (kg) | Motor Cycle (rpm) | Motor Power | Chamber Depth (mm) |

|---|---|---|---|---|---|---|---|---|

| VTM 50 | 50 | 640 | 305 | - | - | - | - | - |

| VTM 300 | 300 | 1200 | 550 | - | - | - | - | - |

| VTM 600 | 600 | 2700 | 465 | - | - | - | - | - |

| VTM 900 | 900 | 3800 | 465 | - | - | - | - | - |

VM Series

Tip: For VM series machines, consider the chamber width and total height when integrating into your workspace for efficient operation and maintenance.

| Machine Type | Chamber Width A (mm) | Inside Width B (mm) | Unload Height C (mm) | Total Length D (mm) | Total Width E (mm) | Total Height F (mm) | Capacity (L) | PU Thickness (mm) | Weight (kg) | Motor Cycle (rpm) | Motor Power (kW) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| VM20Y | 170 | 530 | 425 | 710 | 540 | 235 | 20 | 15 | 125 | 1500 | 0.75 |

| VM20 Y GR | 170 | 530 | 600 | 1600 | 782 | 235 | 20 | 15 | 200 | 1500 | 0.75 |

| VM35Y | 220 | 590 | 360 | 635 | 620 | 305 | 35 | 15 | 160 | 3000 | 0.65 |

| VM70Y | 300 | 750 | 430 | 795 | 670 | 356 | 70 | 20 | 355 | 3000 | 2 |

| VM150Y | 365 | 870 | 715 | 1200 | 1070 | 490 | 150 | 20 | 496 | 1500 | 1 |

| VM375 Y | 500 | 1500 | 1190 | 1800 | 1120 | 570 | 375 | 20 | 1270 | 1500 | 4/6 |

| VMY2200 | 1100 | 2200 | 1320 | 3900 | 1685 | 967 | 2200 | 25-35 | 4310 | 1500 | 15x2 |

| VMY2200 L | 1300 | 2200 | 1520 | 3900 | 1685 | 967 | 2500 | 25-35 | 4525 | 1500 | 15x2 |

| VMY2400 | 1510 | 1600 | 1900 | 3242 | 2090 | 1370 | 2400 | 25-50 | 4545 | 1500 | 15x2 |

Watch our video on Vibratory Finishing Troughs

Watch our video on Vibratory Finishing noise covers!

Sharmic: Your Partner in Surface Finishing Excellence

Contact us today to discuss how our vibratory finishing machines can revolutionise your surface finishing capabilities.