Circular Vibratory Drying Machines

Our Drying Machines offer a revolutionary approach to drying components after the surface finishing process. Our round vibratory dryers are filled with natural granular materials that absorb moisture from the wet components, providing rapid and effective drying without damaging the components.

Unparalleled efficiency and versatility

Sharmic vibratory drying machines offer a number of advantages over traditional drying methods, including:

Superior drying efficiency

Our machines can dry components to 100% dryness, significantly reducing processing times.

Gentle handling

The natural granular media cushions the components during the drying process, preventing damage or scratching.

Versatility

Easy-opening media discharge door for quick media changes.

Innovative features for seamless operation

Sharmic vibratory drying machines are equipped with a number of innovative features that ensure seamless operation and superior results, including:

- Internal polyurethane lining to prevent component damage and ensures best results.

- Dust Covers: These covers reduce dust levels, making our machines ideal for use in a variety of manufacturing environments.

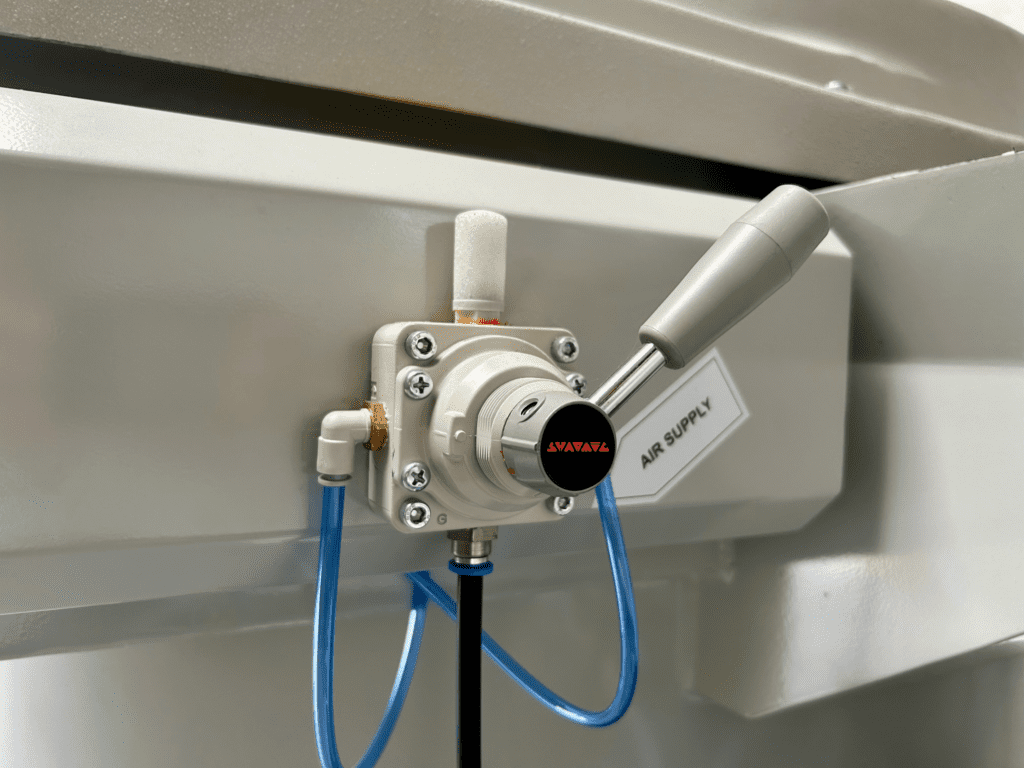

- Pneumatic Control: raises the ramp to unload components after drying.

Enhanced surface appearance and durability

The drying process performed with granules in Sharmic vibratory drying machines provides a clearer appearance of the surface brightness and enhances the durability of the finish. This is because the granules remove any residual polishing compounds or other contaminants that could cloud the surface or reduce its longevity.

Applications across industries

Sharmic Through Vibratory Surface Finishing Machines are widely used in a variety of industries, including:

Automotive

Aerospace

Defence

Jewellery

Metalworking

Plastics processing

Elevate your drying capabilities with Sharmic

Sharmic vibratory drying machines represent the forefront of drying technology. Our machines offer a number of advantages over traditional drying methods, including superior efficiency, gentle handling, versatility, and enhanced surface appearance. With a wide range of features and customisable solutions to meet your specific needs, Sharmic is the ideal partner for all your drying requirements.

Contact us today to learn more about how our vibratory drying machines can revolutionise your manufacturing process.

VRK Drying Machines Technical Data

Discover our VRK series drying machines, optimised for drying components with Maizorb and heating elements at www.sharmic.co.uk. Tip: Select the appropriate capacity and heater power based on your drying needs to ensure efficient moisture removal and component protection.

| Machine Type | Capacity (L) | PU Thickness (mm) | Steel Thickness (mm) | Process Width A (mm) | Inner Diameter B (mm) | Discharge Height C (mm) | Width D (mm) | Length E (mm) | Height F (mm) | Process Height G (mm) | Input Height H (mm) | Outlet Chute J (mm) | Inlet Chute K (mm) | Weight (kg) | Motor Cycle (rpm) | Motor Power (kW) | Heater Power (kW) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| VRK125 K | 125 | PU SPRAY | 5 | 255 | 990 | 751 | 1125 | 1230 | 860 | 335 | 835 | 275 | 300 | 385 | 1500 | 1.1 | 1.8 |

| VRK225 K | 225 | PU SPRAY | 5 | 295 | 1130 | 851 | 1220 | 1395 | 970 | 409 | 945 | 320 | 350 | 500 | 1500 | 2.2 | 3 |

| VRK350 K | 350 | PU SPRAY | 5 | 345 | 1290 | 931 | 1400 | 1585 | 1080 | 474 | 1020 | 385 | 370 | 675 | 1500 | 2.2 | 4 |

| VRK500 K | 500 | PU SPRAY | 5 | 380 | 1510 | 1005 | 1620 | 1800 | 1170 | 534 | 1050 | 420 | 440 | 902 | 1500 | 4 | 4.5 |

| VRK800 K | 800 | PU SPRAY | 6 | 450 | 1750 | 1161 | 1865 | 2055 | 1370 | 632 | 1205 | 495 | 500 | 1540 | 1500 | 4/6 | 6 |

| VRK1100K | 1100 | PU SPRAY | 6 | 490 | 1890 | 1261 | 2002 | 2205 | 1470 | 672 | 1305 | 565 | 600 | 1910 | 1500 | 4/6 | 6 |

Sharmic: Your partner in surface finishing excellence

Contact us today to discuss how our vibratory finishing machines can revolutionise your surface finishing capabilities.