Market Outlook: The Future of Vibratory Surface Finishing

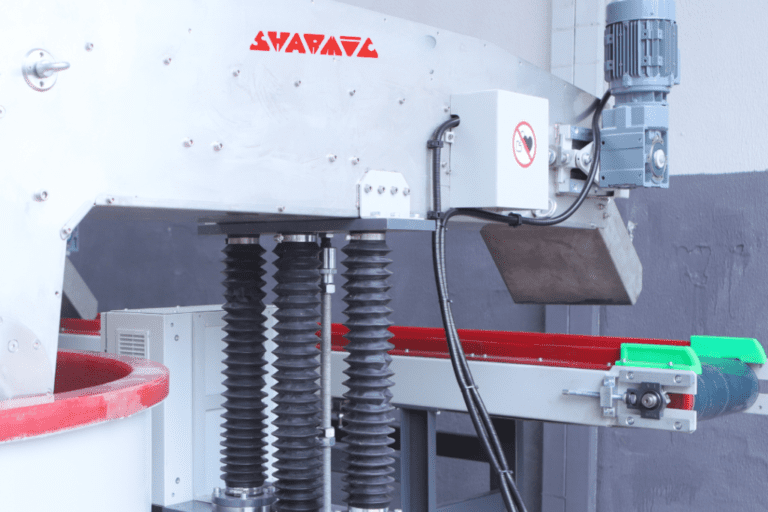

Magnetic separator for component and media separation

At Sharmic Engineering, we remain steadfast in our commitment to maintaining an informed and forward-looking perspective on the trends, innovations, and transformative shifts shaping the vibratory surface finishing sector. As we look to the future, we anticipate that the coming years will present notable advancements, emerging opportunities, and several critical challenges for manufacturers, suppliers, and subcontract service providers alike. This article seeks to provide a considered exploration of the principal factors expected to influence the market and highlight the key considerations businesses should bear in mind as the industry continues to evolve.

Global Market Expansion

The vibratory surface finishing market — encompassing vibratory bowl machines, trough machines, centrifugal finishing systems, rotary barrels, and an extensive array of consumables — is projected to continue its steady trajectory of growth.

Industry analysts indicate that sustained demand across pivotal sectors, including automotive, aerospace, medical device manufacturing, and precision engineering, is fuelling the requirement for dependable and efficient finishing solutions.

Within the United Kingdom and across continental Europe, heightened environmental concerns and increasing regulatory pressures are compelling manufacturers to adopt more sustainable, energy-efficient equipment and consumables. Consequently, we foresee continued innovation in both machinery design and finishing media in order to satisfy elevated standards and evolving customer expectations.

Principal Drivers Influencing the Market

Several key trends are poised to shape the future direction of the vibratory finishing landscape:

Increasing Demand for Precision

As industries strive for enhanced product quality and ever-tighter manufacturing tolerances, the demand for advanced vibratory finishing solutions that deliver repeatability, consistency, and operational efficiency is intensifying.

Sustainability and Environmental Considerations

There is a growing imperative among manufacturers to employ environmentally responsible media, biodegradable compounds, and energy-conserving machinery in alignment with stringent environmental regulations. Moreover, there is rising interest in dry finishing processes — such as those utilising maizorb or walnut shell — which significantly reduce water and chemical consumption.

Automation and Smart Integration

The emergence of Industry 4.0 and smart manufacturing paradigms is propelling demand for vibratory finishing systems capable of seamless integration into automated production lines, offering real-time data monitoring and predictive maintenance capabilities.

Expansion of Subcontract Finishing Services

An increasing number of enterprises are electing to outsource their surface finishing requirements to reputable subcontract service providers such as Sharmic Engineering. This approach enables companies to benefit from high-quality finishing outcomes without the need for substantial capital investment in specialised equipment.

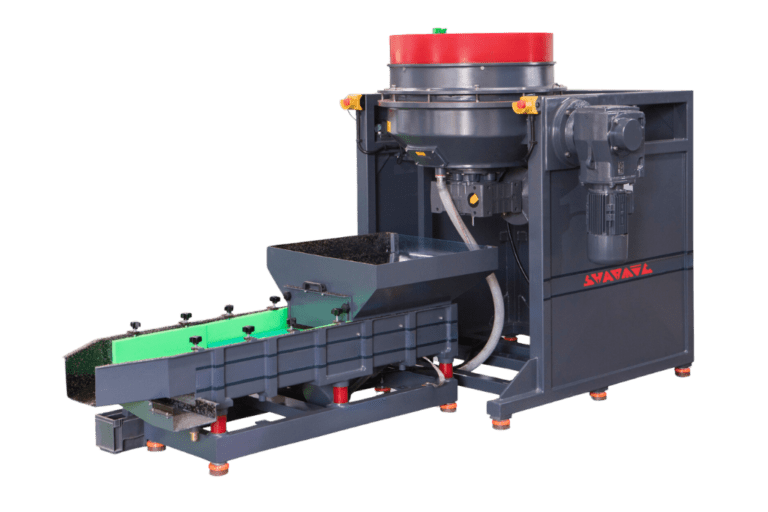

SM50 centrifugal machine with vibratory separator

Anticipated Challenges

Despite a broadly positive market outlook, the industry faces several persistent challenges that warrant careful attention:

Shortage of Skilled Labour

The recruitment and retention of skilled operators and maintenance technicians continue to pose challenges, particularly as equipment grows more sophisticated and technologically advanced.

Regulatory Compliance Pressures

The ongoing evolution of environmental, health, and safety regulations necessitates continuous innovation and operational adaptability to ensure both compliance and sustained efficiency.

Ongoing Innovation and Product Development

To remain competitive in this dynamic environment, manufacturers and suppliers must prioritise innovation. Core areas of focus include:

- Developing multifunctional media that combine cutting, deburring, and polishing functionalities to enhance process efficiency.

- Introducing compounds designed to minimise waste, improve environmental performance, and ensure consistent finishing results.

- Designing modular and scalable systems that enable businesses to adjust their finishing capacity in accordance with shifting production demands.

At Sharmic Engineering, we are actively investing in the development of new products, the enhancement of our consumable offerings, and the expansion of our subcontract finishing services to ensure we continue to meet the evolving needs of our valued clients.

Concluding Remarks

The vibratory surface finishing industry stands at the threshold of significant transformation, presenting compelling opportunities for those companies that prioritise sustainability, automation, and precision. By remaining vigilant to market trends and committing to ongoing innovation, Sharmic Engineering is exceptionally well-positioned to assist our clients in navigating the challenges and capitalising on the opportunities that lie ahead.

We warmly encourage our customers, partners, and industry colleagues to remain engaged with us for the latest updates regarding product innovations, service enhancements, and industry insights as we collectively advance into this promising future.

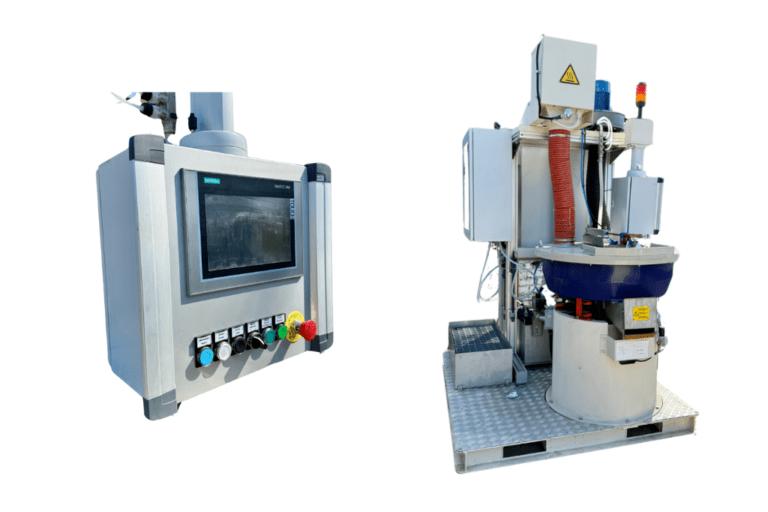

Automatic Pro, All-in-one machine capable of full cycle wet to dry