Maximising the Longevity of Your Vibratory Finishing Equipment

Quick release door VRK drying machinery

Investing in vibratory finishing equipment can greatly improve your production efficiency and product quality, but like any piece of machinery, it requires proper care and maintenance to ensure it performs at its best over time. At Sharmic Engineering, we understand that maintaining vibratory finishing equipment is essential for maximising its longevity and maintaining consistent performance. This blog will explore the best practices for keeping your equipment in top condition and ensuring it serves your business for years to come.

The Importance of Regular Maintenance Vibratory finishing machines are built to withstand continuous use, but to keep them running smoothly, regular maintenance is necessary. Neglecting maintenance can lead to unnecessary downtime, higher repair costs, and even premature failure of parts. A proactive approach to maintenance helps to identify small issues before they become major problems, allowing you to address them quickly and avoid costly repairs.

Greasing and Cleaning Proper lubrication is essential for the smooth operation of vibratory finishing machines. Regularly checking and replenishing lubricants will prevent unnecessary friction and wear, extending the lifespan of key components. Additionally, cleaning the machine regularly helps remove debris, dust, and other particles that can affect the machine’s performance. Clean machinery runs more efficiently, reduces energy consumption, and ensures a consistent finish on your components.

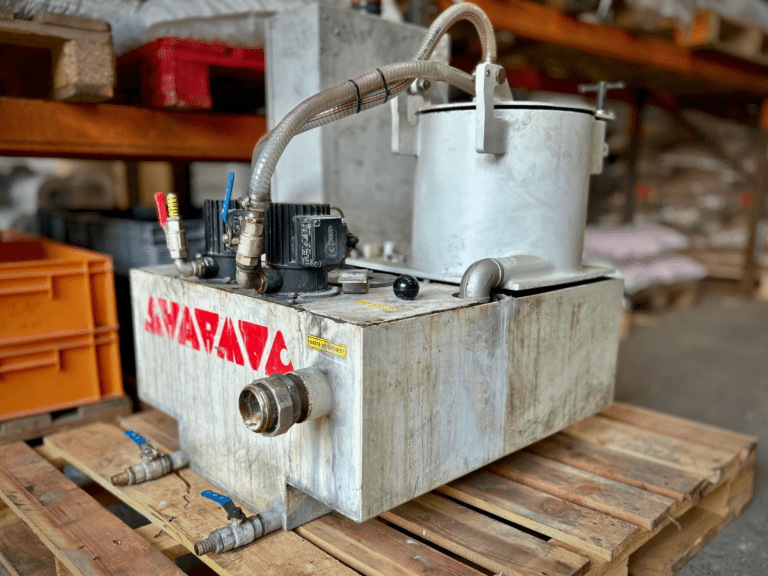

Water treatment unit back for repair

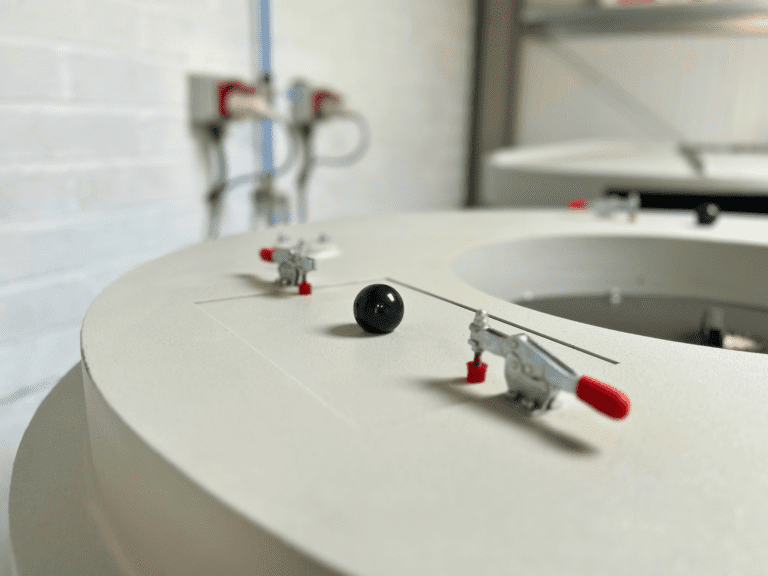

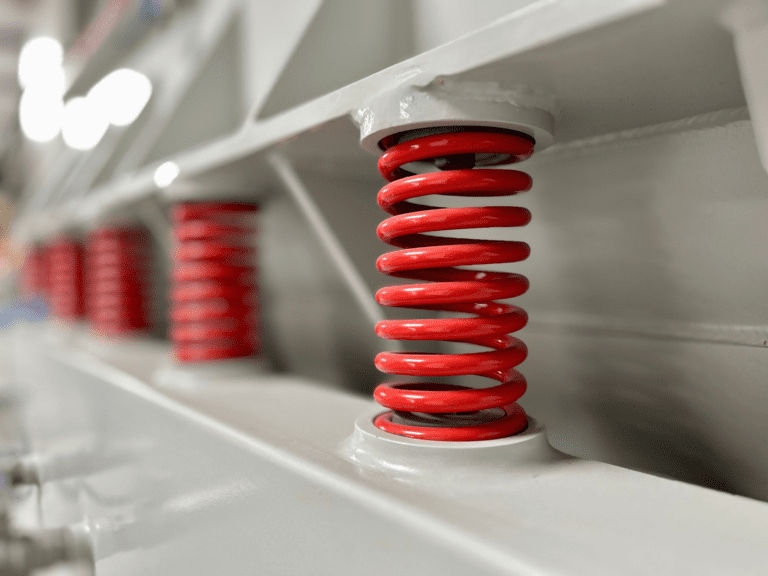

Inspecting Wear Components such as the bowl lining, motors, and springs are subject to wear over time. Regularly inspecting these parts can help you identify any signs of damage or excessive wear. By replacing worn components promptly, you can avoid more significant damage that could disrupt the finishing process. At Sharmic Engineering, we offer high-quality replacement parts and offer expert advice on maintaining your machinery.

Calibration and Alignment Ensuring that your vibratory finishing machine is calibrated and aligned correctly is vital for optimal performance. Over time, vibrations may cause slight misalignments, which can impact the efficiency of the machine and the quality of the finish. Regular calibration ensures the machine is running as it should, maintaining consistent results and improving the overall quality of your products.

Training Your Operators Ensuring your operators are trained to use the equipment properly is one of the most effective ways to increase the longevity of your vibratory finishing machines. Proper training ensures that operators understand how to adjust settings, load the machine correctly, and identify potential issues before they become major problems. At Sharmic Engineering, we offer training services to help your team get the most out of your equipment.

Conclusion Maintaining your vibratory finishing equipment is essential for ensuring it runs efficiently and lasts for years. By following proper maintenance procedures, inspecting key components, and investing in regular training for your operators, you can maximise the lifespan of your machinery and improve overall production efficiency. Sharmic Engineering is here to support you with high-quality replacement parts and expert advice on equipment care.

Vibratory springs, free from debris