Single Phase Vibratory Tumblers

Our range of single-phase vibratory finishing machines that are ideal for small workshops and facilities where there is no three-phase power supply. These machines are simple to use and maintain, and they can be used to perform a variety of finishing processes, including deburring, polishing, and cleaning on a a wide variety of materials, including metal, plastic, and ceramics.

VA Series Finishing Machines

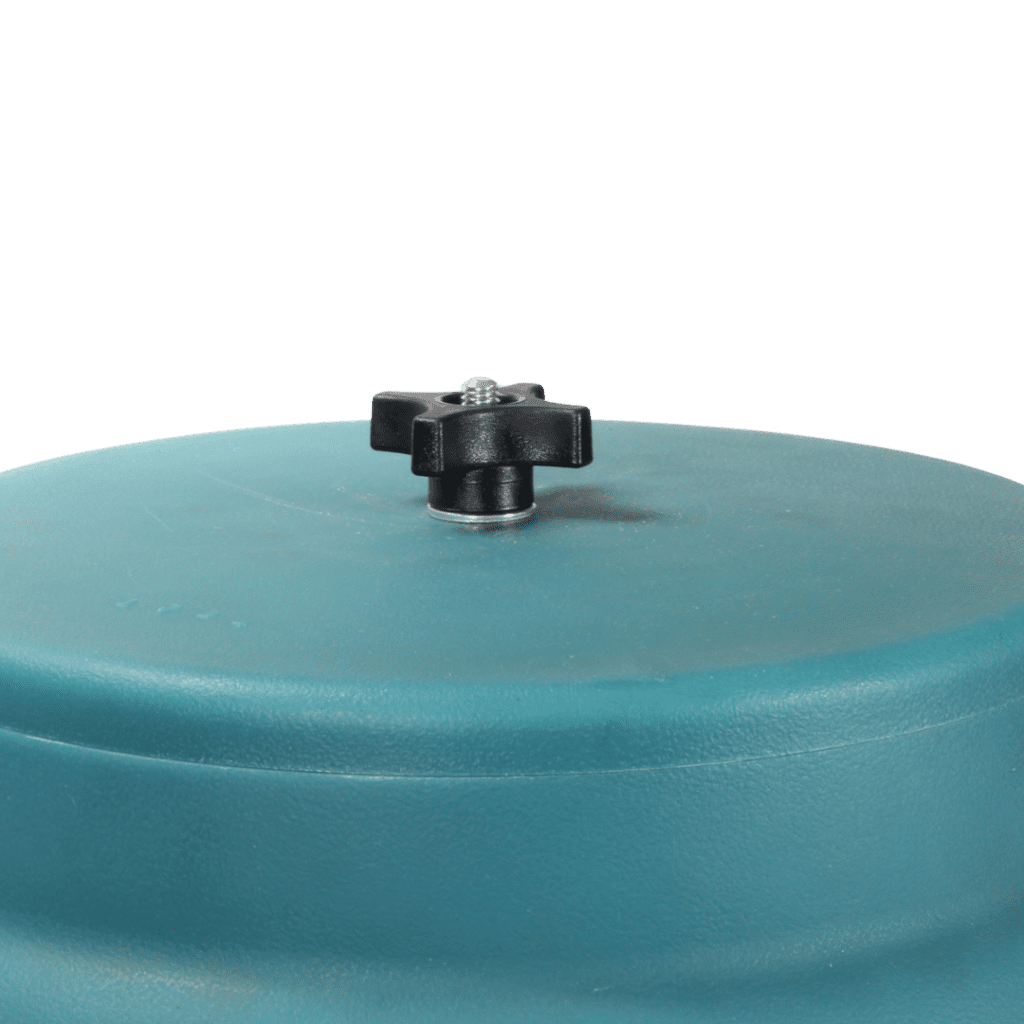

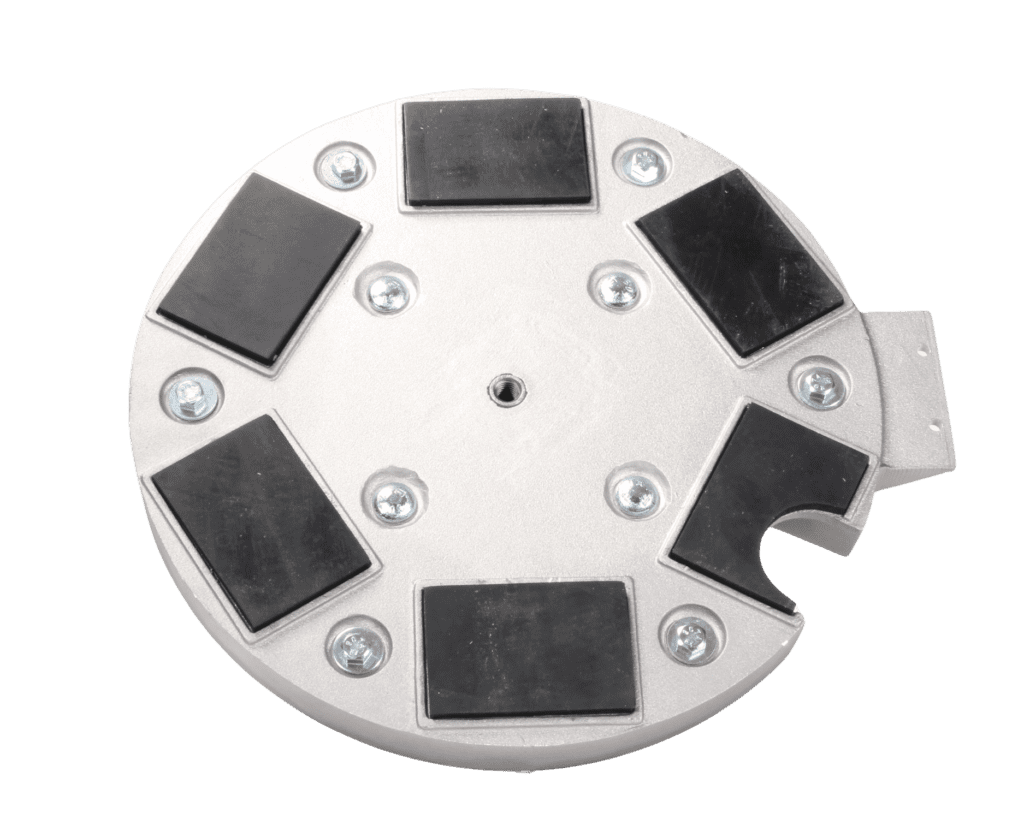

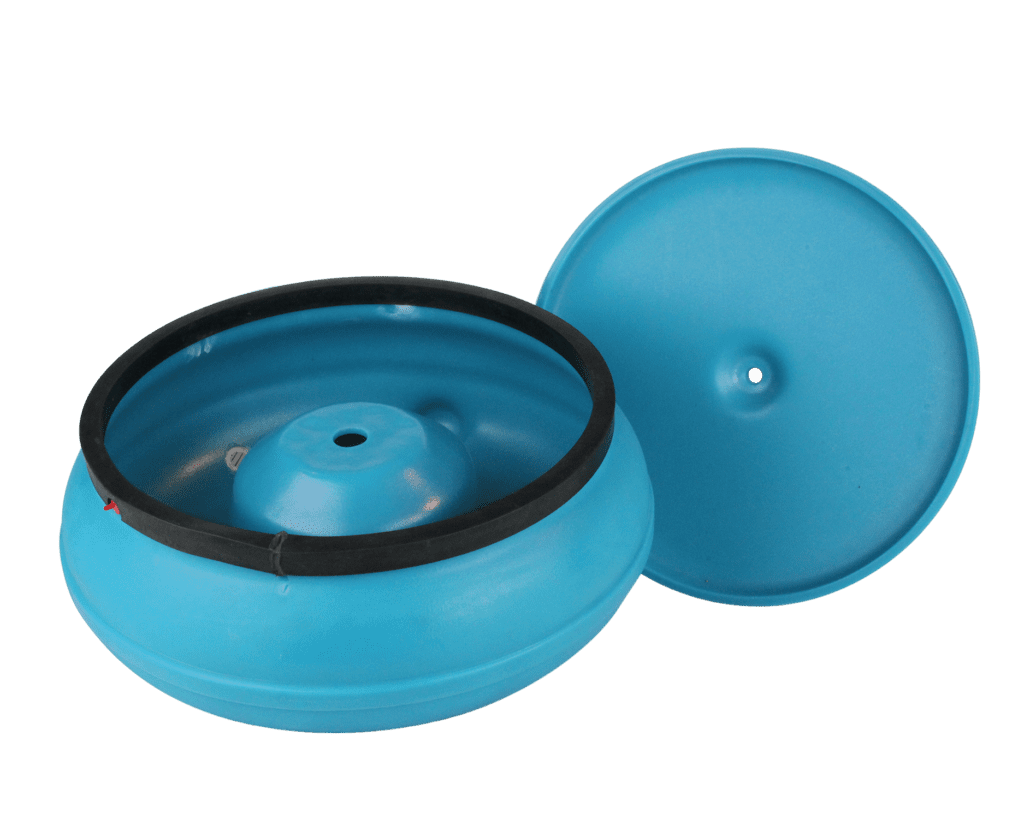

The VA series of vibratory finishing machines from Sharmic Engineering is ideal for small batches of small components. These machines are available in three sizes: VA18, VA25, VA40, and VA75. The VA25 and VA40 machines are ball burnishing models, while the VA75 machine is a standard model.

All VA series machines come complete with an outlet and lid. The VA**/SS model for the VA25 and VA40 machines also includes a discharge door. The VA75/DC model includes a discharge door for easier unloading. The VA**/TD model for the VA40 and VA75 machines includes a tilting device for the bowl.

Single-phase small vibratory finishing machines are ideal for polishing, deburring and achieving a surface finish on small parts. They are particularly well-suited for:

Small workshops or hobbyists: These machines require a standard household electrical outlet 220/60v which most workshops and homes already have, unlike three-phase machines used in larger operations.

Small batch processing: Due to their smaller size, they are suited for processing smaller quantities of parts.

Here are some of the applications:

Deburring: Removing rough edges or imperfections left behind from the manufacturing process.

Polishing: Creating a smooth and shiny surface on the parts.

Superfinishing: Achieving an ultra-smooth surface finish on critical parts.

Overall, single-phase small vibratory finishing is a cost-effective and efficient solution for small-scale metal finishing need

Information

| Model | Diameter | Bowl Width | Bowl Depth | Capacity/Litre |

|---|---|---|---|---|

| TV5 | 8 | 4 | 3.75 | 1.4 |

| TV10 | 10 | 3.5 | 5 | 2.8 |

| VA18 | 12 | 4 | 4.25 | 5.06 |

| VA25 | 14 | 3.5 | 5.75 | 6.15 |

| VA40 | 17 | 4.25 | 7 | 9.8 |

| VA75 | 21 | 7 | 9.5 | 21.00 |

Watch our video on Vibratory Finishing

Sharmic: Your Partner in Surface Finishing Excellence

If you are looking for a fast, efficient, and versatile way to surface treat metal and plastic items, then a tilting rotary barrel system is the perfect solution for you.