New to Vibratory Finishing?

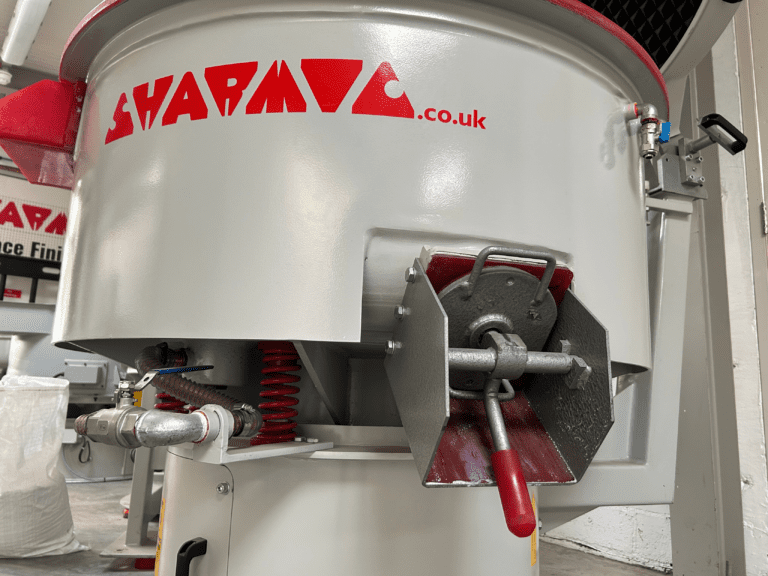

Quick release door for easy unload/change over of media

Vibratory finishing is a widely used process in the manufacturing industry, providing an efficient and cost-effective way to improve the surface of various components. Whether you are involved in metalworking, automotive, aerospace, or even jewellery production, vibratory finishing could significantly enhance your product quality. But, if you are new to the process, you might be wondering what it is all about. Here is a comprehensive guide to help you get started with vibratory finishing.

What is Vibratory Finishing?

At its core, vibratory finishing is a mass finishing process. It involves placing components into a vibratory bowl or trough that contains a mixture of finishing media and compounds. The vibratory action causes the media to rub against the components, effectively cleaning, deburring, polishing, or preparing them for further processing, like coating or plating. This method is ideal for smoothing rough edges, removing burrs, and creating a uniform surface finish on a wide range of materials.

How Does It Work?

The process begins by loading a vibratory machine with your components, media, and compounds. When the machine is activated, its motor creates a vibratory motion. This motion causes the media to flow around the components, resulting in friction that abrades their surfaces. The specific type of media and compound used, along with the speed and intensity of the vibration, determines the final finish of the product.

Types of Vibratory Machines

- Vibratory Bowl Machines

These are the most common type of vibratory machines, suitable for a wide range of finishing tasks. They come in both manual unload and automatic unload versions. The latter allows for continuous processing, where components can be automatically separated from the media and collected, speeding up production. - Vibratory Trough Machines

Trough machines are ideal for larger, longer components that may not fit comfortably in a bowl. Their rectangular shape accommodates a variety of sizes and shapes, offering flexibility for more specialised projects. - Centrifugal Finishing Machines

These machines use centrifugal force to accelerate the finishing process, often used when a faster cycle time is required. They are particularly effective for achieving fine finishes or polishing smaller, delicate components.

TCX porcelain, cylinder shaped for polishing

Finishing Media and Compounds

The choice of finishing media and compounds is crucial for achieving the desired results. There are several types of media available, each suited to specific tasks:

- Plastic Media: Ideal for general-purpose deburring and polishing, plastic media is lightweight and less aggressive, making it suitable for softer metals and delicate components.

- Ceramic Media: This is more aggressive and ideal for heavy-duty deburring or cleaning applications. Ceramic media is commonly used for harder metals and is effective for removing sharp edges or large burrs.

- Porcelain Media: Porcelain media is primarily used for polishing, providing a smooth, high-gloss finish. It is especially useful for components that need a fine, aesthetic surface.

In addition to media, compounds—available in liquid, paste, or powder form—play an essential role in lubricating the process, enhancing cleaning, or aiding in rust prevention. The combination of the right media and compound can significantly impact the efficiency of the process and the quality of the finish.

Benefits of Vibratory Finishing

- Efficiency: The ability to process multiple components simultaneously makes vibratory finishing one of the most time-efficient methods of surface finishing.

- Versatility: With the right combination of media and machinery, vibratory finishing can manage a wide variety of materials and component shapes, from small, intricate pieces to larger, heavier parts.

- Consistency: Unlike manual finishing methods, vibratory finishing ensures a uniform surface finish on all components, reducing variability and improving quality control.

- Cost-Effective: Due to its ability to process large quantities of components in a single run, vibratory finishing is an economical choice for many manufacturers.

Subcontract Finishing Services

If you do not have the equipment or resources to conduct vibratory finishing in-house, subcontract finishing services offer a convenient alternative. These services allow you to send in your components for professional finishing, ensuring high-quality results without the upfront investment in machinery and media.

At Sharmic Engineering, we not only offer a comprehensive range of vibratory machines, media, and compounds, but we also provide a complete subcontract finishing service. Whether you need deburring, polishing, cleaning, or any other finishing process, we can manage the work for you.

Ready to Get Started?

Whether you are new to vibratory finishing or looking to upgrade your existing setup, understanding the basics is essential for choosing the right equipment and materials. If you need advice or support, the experts at Sharmic Engineering are here to guide you through the process, ensuring you achieve the best results for your specific application.

Visit our website at www.sharmic.co.uk for more information on our range of vibratory finishing products and services.

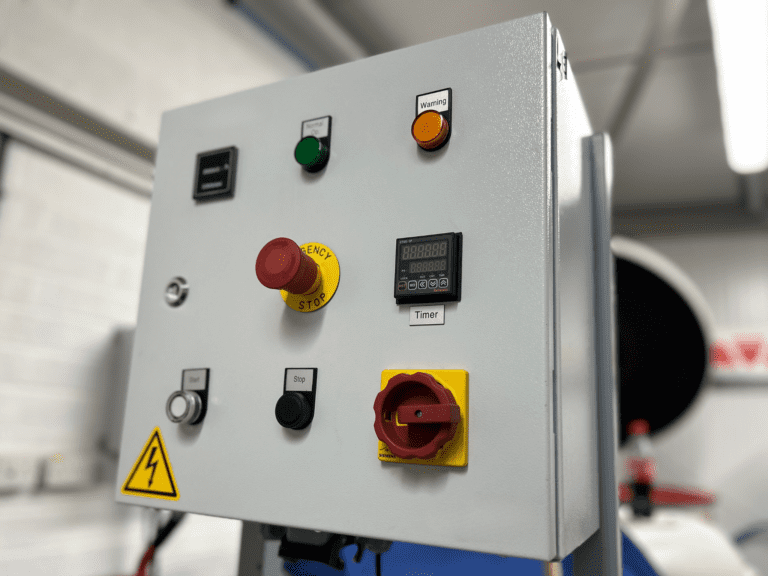

Control panel