Latest News & Blog

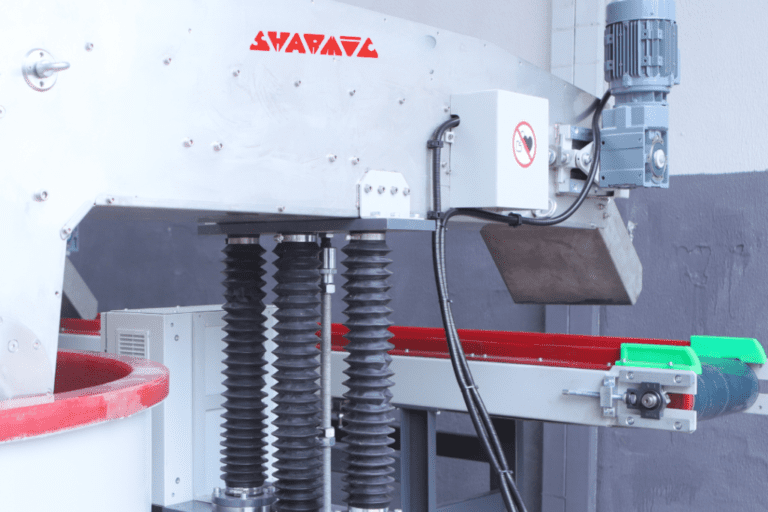

Discover the VRX Range: Automatic Unloading Vibratory Bowls Revolutionising Surface Finishing

In the fast-paced world of manufacturing, efficiency isn’t just a buzzword—it’s a necessity. Whether you’re tackling deburring, radiusing, polishing, edge breaking, degreasing, cleaning, or surface smoothing on ferrous and non-ferrous metals, plastics, ceramics, natural stones, glass, wood, or rubber products, the right equipment can make all the difference.

Revolutionise Your Post-Finishing Process with Sharmic Vibratory Drying Machines

In the fast-paced world of surface finishing, drying components efficiently without compromising quality is a significant change. At Sharmic, our circular vibratory drying machines deliver 100% dryness using natural granular media like Maizorb, absorbing moisture rapidly while protecting delicate parts from damage.

The Complete Guide to Vibratory Finishing: Process, Machines, and Benefits

Vibratory finishing made simple. Discover how Sharmic’s machines, media, and compounds deliver consistent, high-quality surface finishes every time.

Vibratory Trough Finishing: Precision Surface Treatment for Components

Vibratory trough finishing is a vital surface finishing process widely utilised across numerous manufacturing sectors. This technique employs vibratory trough machines to deliver consistent deburring, polishing, cleaning, and edge rounding, thereby enhancing the quality and performance of industrial components.

Your Go-To for Vibratory Finishing Know-How

Sharmic Engineering blog – your inside look into the world of vibratory surface finishing. Based in Stourport-on-Severn, Worcestershire, we’ve spent decades helping UK manufacturers get the best results from their surface finishing processes.

Choosing the Right Media

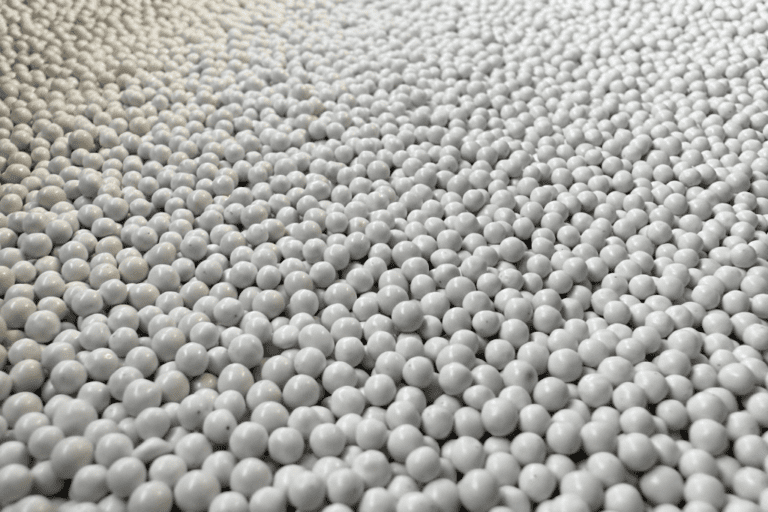

In any vibratory surface finishing operation, selecting the correct media is absolutely critical. The type, shape, and size of media you use will directly affect the final finish on your components, as well as the efficiency, consistency, and cost-effectiveness of the process.

What Do Our Machines Do?

What is a Vibratory Finishing Machine?

A vibratory finishing machine is used to improve the surface of metal or plastic components. It works by shaking or vibrating a container filled with parts, abrasive media and a finishing compound. The constant movement causes the parts to rub against the media, which helps to remove sharp edges, smooth surfaces or polish the components.

This process is commonly used in industries such as automotive, aerospace and engineering. It is ideal for deburring, cleaning and preparing surfaces before further treatments like painting or plating. The machine can process many parts at once, making it a cost-effective solution for high-volume production.

Why Correct Media Type, Shape, and Size Are Essential in Vibratory Finishing

In the world of vibratory finishing, success depends on more than just the machine — it depends on selecting the correct media type, shape, and size for the application. At Sharmic, we work with customers across industries to optimise their finishing processes, ensuring that every component achieves the desired result efficiently, safely, and without unnecessary delays.

Market Outlook: The Future of Vibratory Surface Finishing

We remain steadfast in our commitment to maintaining an informed and forward-looking perspective on the trends, innovations, and transformative shifts shaping the vibratory surface finishing sector.

UK Vibratory Surface Finishing Specialists

Sharmic supplies a comprehensive line-up of mass finishing machines, consumables and equipment tailored to diverse components and applications. Each machine type offers a specific finishing benefit.

New to Vibratory Finishing?

Vibratory finishing is a widely used process in the manufacturing industry, providing an efficient and cost-effective way to improve the surface of various components. Whether you are involved in metalworking, automotive, aerospace, or even jewellery production, vibratory finishing could significantly enhance your product quality.

How Vibratory Finishing Machines Can Save Your Company Money

In today’s highly competitive business environment, companies must find ways to increase productivity and reduce costs without sacrificing quality. Vibratory finishing is a proven solution for businesses looking to save money in their manufacturing processes.

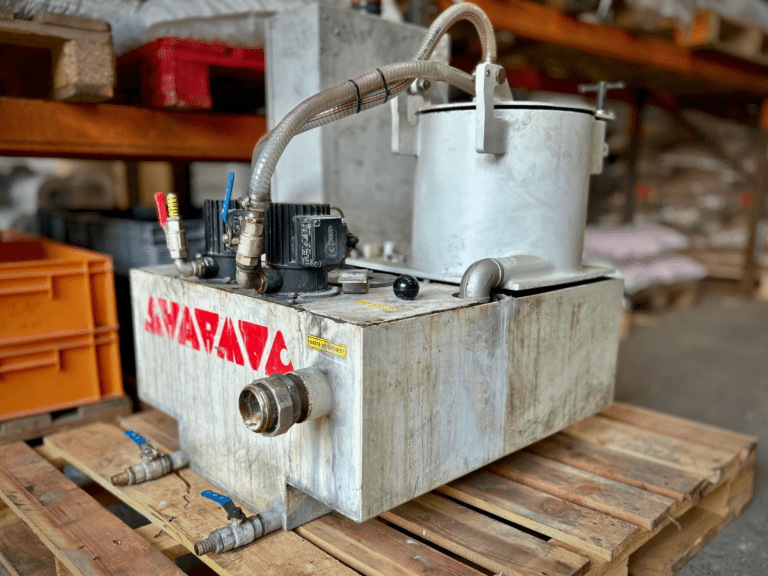

Maximising the Longevity of Your Vibratory Finishing Equipment

The Importance of Regular Maintenance Vibratory finishing machines are built to withstand continuous use, but to keep them running smoothly, regular maintenance is necessary. Neglecting maintenance can lead to unnecessary downtime, higher repair costs, and even premature failure of parts.

Why Use Centrifugal Finishing Machines?

If you’re looking to speed up your finishing process without compromising on quality, centrifugal finishing machines are well worth considering. They use fast, powerful spinning motion to achieve a high-quality finish in far less time than other methods.

How Vibratory Trough Machines Can Benefit Your Business

Vibratory trough machines are an excellent solution for businesses seeking to process large, heavy components that require mass finishing. These machines are ideal for bulk finishing and are capable of handling bigger components than vibratory bowl machines.

What do powder compounds do?

We offer a tailored range of powder type surface finishing compounds designed for grinding, lapping, polishing, deburring, and more. Each product is developed to address the unique needs of both ferrous and non-ferrous metals, ensuring optimal results in vibratory finishing, hand finishing, or precision operations.

What do liquid compounds do?

Our liquid compounds are carefully formulated to address a wide variety of cleaning, polishing, degreasing, and protective needs across a broad spectrum of materials and applications. Whether you’re working with steel, aluminium, brass, or more delicate alloys, our expertly developed liquids deliver consistent and high-quality results.

Why Quality Media and Compounds Matter in Vibratory Finishing

When you’re aiming for top-quality results in vibratory finishing, the consumables you use can make just as much difference as the finishing equipment itself. At Sharmic Engineering, we supply a wide range of high-grade media and compounds designed to support and improve the finishing process.

Why Use Vibratory Finishing?

If you’re looking for a fast, efficient, and cost-effective way to finish your parts, vibratory finishing is one of the best options out there. It’s perfect for industries where parts need a smooth, polished, or deburred surface, such as automotive, aerospace, and engineering.

The Role of Vibratory Finishing in Automotive Manufacturing

When it comes to the automotive industry, few sectors place higher demands on precision, performance, and quality. Every part, from the smallest gear to the largest panel, must perform flawlessly and meet exacting standards.