Latest News & Blog

How Implementing Vibratory Finishing Can Deliver Cost-Effective Production Gains

Vibratory finishing works by gently moving parts in contact with specially designed media. The vibration does the hard work: removing burrs, smoothing edges, polishing surfaces. What’s clever is the consistency it delivers.

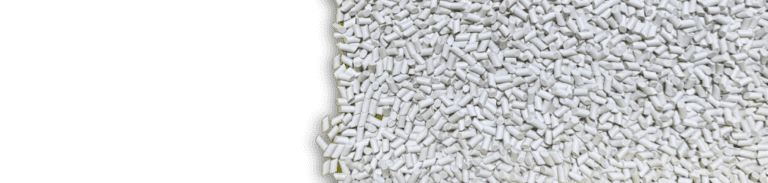

Understanding Porcelain Media in Vibratory Surface Finishing

Porcelain media is a type of non-abrasive or mildly abrasive finishing media, typically made from white clay materials mixed with other fine ingredients, then fired at high temperatures. It’s harder and denser than plastic media, but much gentler than ceramic.

Understanding Ceramic Media in Vibratory Surface Finishing

Ceramic media is a type of abrasive material used in vibratory finishing machines to clean, deburr, smooth or polish components. It is made from a mixture of abrasive grains, typically aluminium oxide, and a bonding agent that is shaped and fired at high temperatures to form durable, long-lasting media.

Understanding Plastic Media in Vibratory Surface Finishing

What is Plastic Media?

Plastic media is a synthetic abrasive material used in vibratory finishing applications. It is typically manufactured from a polyester resin base, combined with abrasive materials such as aluminium oxide or silica. These media are moulded into a variety of shapes including cones, pyramids, cylinders, wedges, and tri-stars to accommodate the specific requirements of different component geometries.

Why Vibratory Finishing is the Key to Efficient Production

In today’s highly competitive manufacturing environment, companies are continuously searching for ways to enhance efficiency, reduce costs, and ensure a consistent level of quality. One such method that stands out is vibratory finishing. It is a powerful technique that not only optimises production but also ensures components are finished to the highest standards. At Sharmic Engineering, we offer a wide range of vibratory finishing solutions, and in this blog, we’ll delve deeper into why it should be a cornerstone of your business.

How Vibratory Finishing Can Boost Your Company’s Production, Save Money, and Free Up Operator Time

In today’s competitive manufacturing industry, efficiency and precision are critical. Whether you’re involved in metalworking, automotive components, or precision engineering, the finishing process plays a significant role in ensuring the quality of your products. Vibratory finishing is one of the most advanced and efficient techniques available, and it can significantly improve your production workflow, reduce errors, save money, and free up valuable operator time.