Vibratory Trough Finishing: Precision Surface Treatment for Components

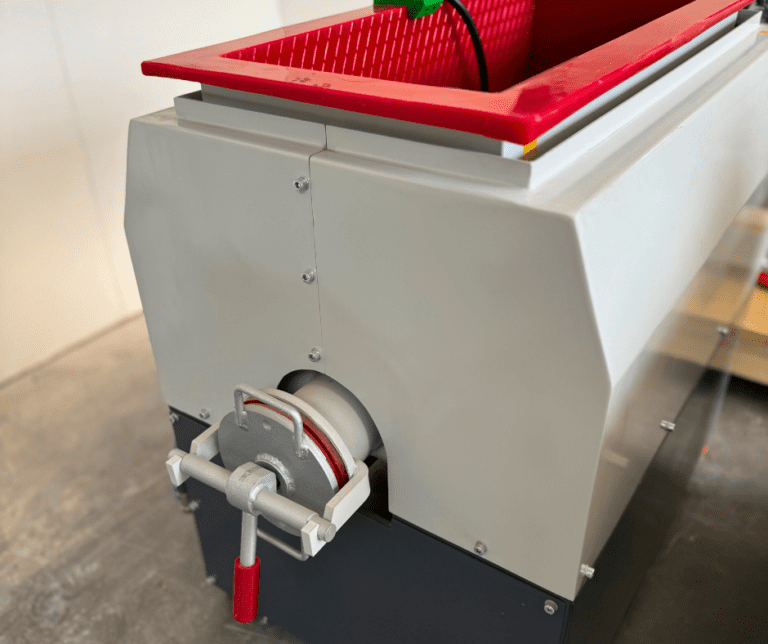

Side view of vibratory trough machine showing interior lining and discharge door close-up

Vibratory trough finishing is a vital surface finishing process widely utilised across numerous manufacturing sectors. This technique employs vibratory trough machines to deliver consistent deburring, polishing, cleaning, and edge rounding, thereby enhancing the quality and performance of industrial components.

Understanding Vibratory Trough Finishing

Vibratory trough finishing operates through a trough-shaped vibratory machine that generates a controlled circular motion. This motion agitates both parts and abrasive media simultaneously, creating uniform friction that removes burrs and refines surfaces to meet stringent industrial specifications. Unlike vibratory bowl machines, trough finishers are ideal for larger or irregularly shaped components that require longer processing chambers.

Benefits of Vibratory Trough Finishing

- Effective Deburring and Edge Rounding

Precisely eliminates sharp edges and burrs to improve safety and product functionality. - Consistent Surface Polishing and Cleaning

Delivers a uniform finish while removing contaminants such as oil, rust, and dirt. - Versatile Material Compatibility

Suitable for metals including steel, aluminium, brass, as well as various plastics. - Reliable and Repeatable Results

Ensures uniform surface quality across large production volumes. - Increased Operational Efficiency

Automates finishing processes, reducing manual labour and improving throughput. - Suitable for Larger or Complex Parts

Accommodates components that may not be suited to bowl finishing machines.

How Vibratory Trough Finishing Works

The vibratory trough machine transmits vibratory energy through its base, producing a circular motion inside the trough. This action causes the media and components to move together, enabling effective surface finishing through friction and abrasion. Process parameters such as vibration intensity and cycle duration are adjustable to suit specific finishing requirements.

Key Components in Vibratory Trough Finishing

- Vibratory Trough Machine Constructed for durability and continuous operation, available in a range of sizes to suit production demands.

- Finishing Media Includes plastic, ceramic, porcelain media and natural options such as walnut shell and maizorb, selected based on component material and desired finish.

- Finishing Compounds Applied in liquid, paste, or powder form to enhance cleaning, reduce friction, and improve surface quality.

- Separation and Drying Systems

Used to separate finished components from media and prepare parts for subsequent processing.

Compact Vibratory Trough with Outlet Valve

Applications of Vibratory Trough Finishing

- Automotive Manufacturing

Refining engine components, gears, fasteners, and valves. - Aerospace Industry

Finishing turbine blades and structural parts. - Medical Devices

Producing burr-free surgical instruments and implants. - General Engineering

Preparing components for assembly or coating. - Electronics

Cleaning and polishing small metal parts to ensure electrical conductivity.

Optimising Vibratory Trough Finishing

- Media Selection Choosing the appropriate media type is critical, ceramic media for aggressive deburring or plastic for fine polishing.

- Compound Usage Specialised compounds improve process efficiency and final surface finish.

- Cycle Time Control

Adjust finishing duration according to part complexity and surface finish requirements. - Routine Maintenance

Regular machine inspection and upkeep maintain consistent performance and longevity.

Advantages Over Alternative Finishing Methods

Compared to tumbling or centrifugal finishing, vibratory trough finishing provides a gentler process, reducing risk of part deformation. It also accommodates mixed part batches more effectively and is typically more energy efficient.

Conclusion

Vibratory trough finishing remains an essential process for manufacturers requiring precise and reliable surface treatment. This finishing method offers comprehensive benefits, from deburring and polishing to cleaning, applicable to a broad range of materials and industries. Selecting the correct media and compounds and maintaining optimal machine settings ensures consistent high-quality finishes while maximising operational efficiency.

For expert advice on vibratory trough finishing machinery, media including plastic, ceramic and porcelain, and finishing compounds in liquid, paste or powder form, or to discuss subcontract finishing services, contact Sharmic. Based in Worcestershire, Sharmic delivers tailored surface finishing solutions supported by extensive industry expertise.

Before and After: Large Handbrake Restored by Vibratory Surface Finishing