Your Go-To for Vibratory Finishing Know-How

TC1 6mm triangular ceramic media

Sharmic Engineering Blog – Your Go-To for Vibratory Finishing Know-How

Welcome to the Sharmic Engineering blog – your inside look into the world of vibratory surface finishing. Based in Stourport-on-Severn, Worcestershire, we’ve spent decades helping UK manufacturers get the best results from their surface finishing processes. Whether you’re looking for vibratory finishing machines, consumables or full subcontract finishing services, you’re in the right place.

This blog is here to give you practical advice, industry updates and expert tips to help you get more from your finishing set-up – whether you’re polishing, deburring or just exploring your options.

What Is Vibratory Finishing and Why Should You Care?

Vibratory finishing is a process used to smooth, clean, and improve the surface of components. It’s widely used across industries like aerospace, automotive, medical, and general engineering. The process removes burrs, rust and sharp edges while leaving a clean, consistent finish.

At Sharmic, we supply everything from vibratory bowl machines (manual and automatic unload) to single-phase tumblers and centrifugal finishing machines – all designed to help you finish components faster, more efficiently and with better results.

What’s New in Vibratory Finishing Equipment

Technology never stands still – and neither do we. In today’s fast-paced production world, performance matters. Our machines are constantly evolving, whether it’s more energy-efficient vibratory troughs or improved control systems for our centrifugal machines.

How to Choose the Right Finishing Media

The media you use plays a big part in the end result. We offer a wide range of ceramic, plastic, and porcelain media – along with natural options like maizorb and walnut shell. Each type is best suited to different jobs, whether it’s heavy-duty deburring or light polishing.

We’ll share advice on how to pick the best media for your materials, whether you’re working with metals, plastics, or composites – and help you get better results without wasting time or money.

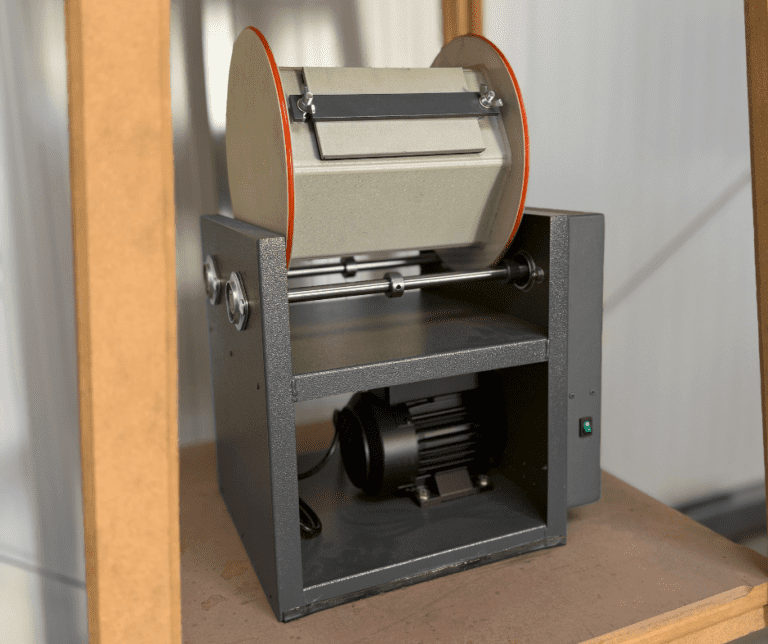

Single-Phase RotaSeries Rotary Barrel

What You Need to Know About Finishing Compounds

Finishing compounds work alongside your machine and media to boost cleaning power, surface brightness and corrosion resistance. We supply them in liquid, powder and paste form. In future and past blog posts, we’ll break down the best compound choices for different materials, how to use them properly and what results you can expect.

Subcontract Finishing – When You Need a Helping Hand

If you don’t have finishing equipment in-house, we’ve got you covered. Our subcontract division can take care of vibratory finishing, drying, and polishing for you. Whether it’s a one-off job or regular production work, we’ll get your parts finished to a high standard – quickly and consistently.

Saving Costs and Staying Green

Energy bills, waste disposal and downtime all cost money. That’s why we’re focused on helping customers cut waste and boost efficiency with smart, energy-saving finishing systems. We’ll share tips on how to keep running costs down, reduce media usage and get more out of your current setup – or when it might be worth upgrading to a newer machine.

Why Work with Sharmic Engineering?

We’re not just here to sell machines. At Sharmic Engineering, we’re a team that genuinely knows and cares about vibratory finishing. Whether you need advice, equipment, or someone to do the finishing for you – we’ve got the knowledge and the tools to help.

SX-19LS HD Degrease Liquid Compound 25L