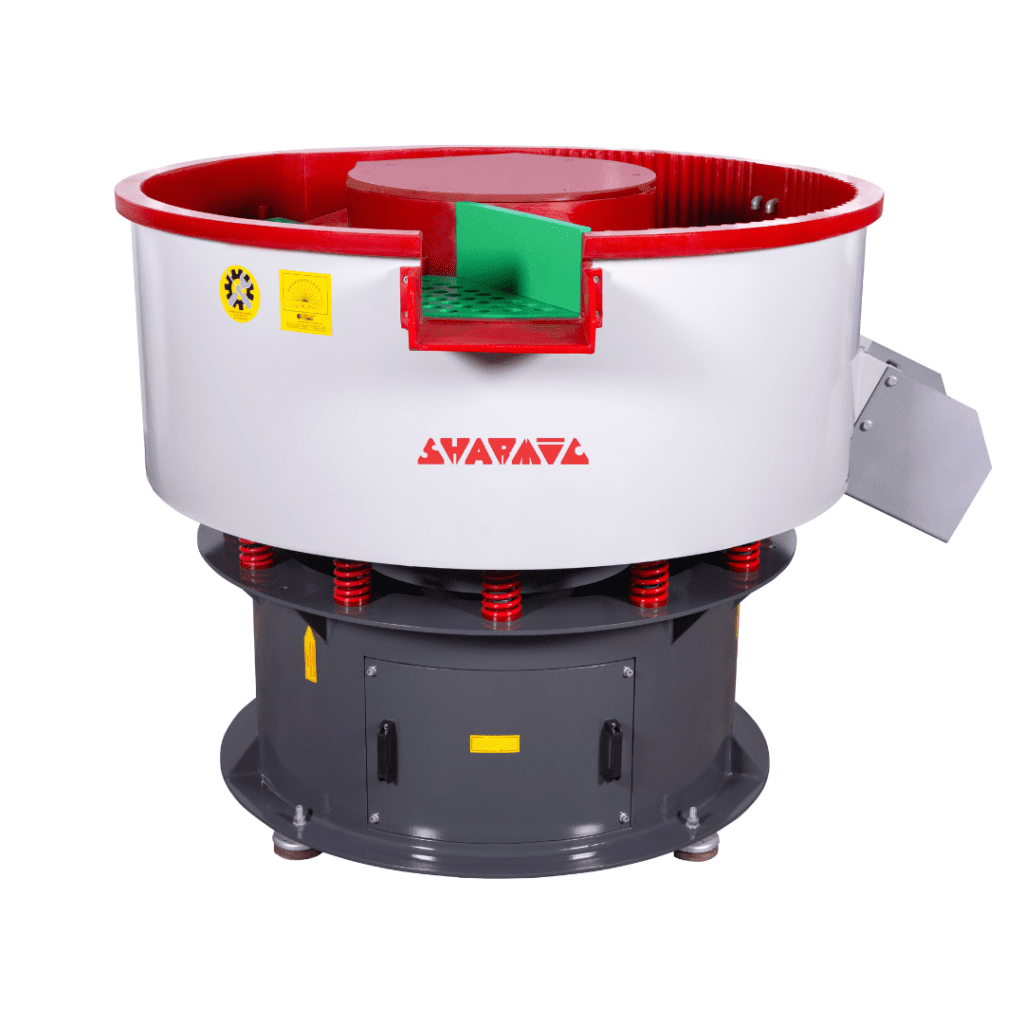

Automatic unloading vibratory machinery

Our finishing machines offer exceptional flexibility and efficiency for a wide range of applications. Our machines are widely used in various industries, providing comprehensive solutions for deburring, radiusing, polishing, edge breaking, degreasing, cleaning, surface smoothing, and similar operations on a variety of materials, including Ferrous and None Ferrous metals, plastics, ceramics, natural stones, glass, wood, and rubber products.

Standard features for unwavering quality

Designed to handle parts of all sizes, from small and delicate components to large and heavy pieces. Our extensive range of machine sizes ensures that we have the perfect solution for your specific production requirements.

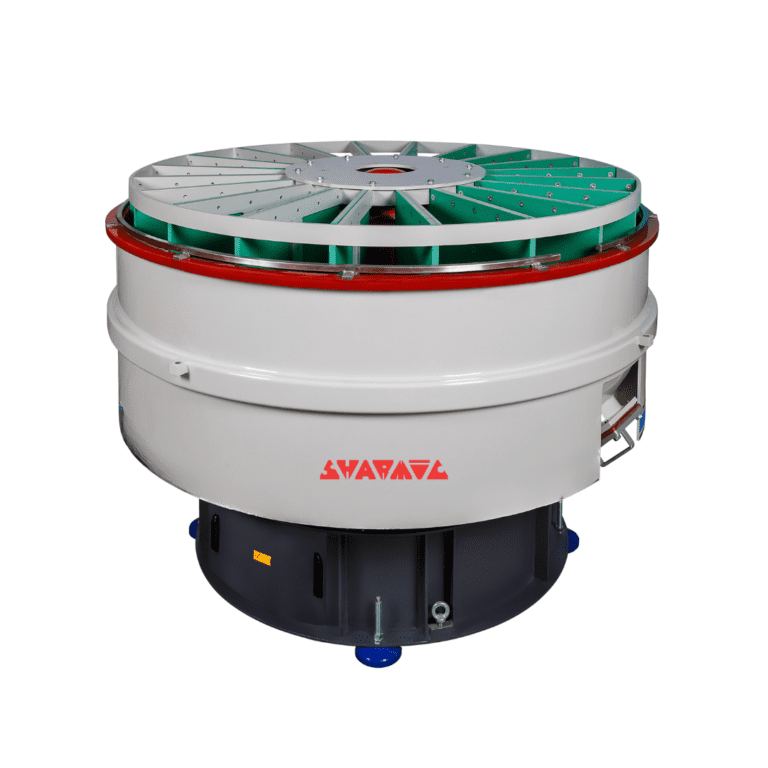

Enjoy the benefits of our diverse range of material capacities, automated solutions, and integrated drying and wastewater treatment systems. Our commitment to innovation extends to our technological testing laboratories, where we continuously develop and refine our process solutions to meet the evolving needs of our customers.

With a vast database of thousands of proven solutions, we carefully select and tailor our offerings to address the unique surface treatment requirements of each customer. Our dedicated team of experts collaborates closely with you to understand your specific needs and provide the optimal solution for your application.

We are committed to providing our customers with exceptional value and long-lasting service. Our test lab offers comprehensive sample process studies to determine the most suitable machine systems, surface finishing abrasives, and processes for your production needs.

Experience the Sharmic difference

Our customers benefit from:

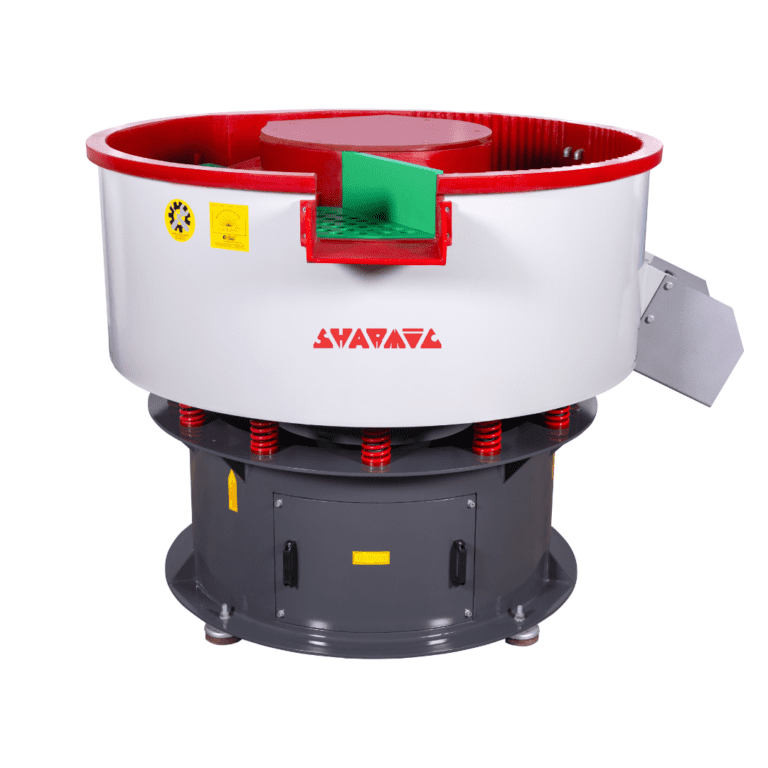

Free Control Panels with the VRX Series

Quick Release Unload Screens

Automatic Greasing

10-15% More Efficient

Optional Pneumatic Unload Ramp

Unleash the power of vibratory surface finishing

Partner with Sharmic and discover the transformative power of our vibratory surface finishing machines. Our commitment to quality, innovation, and customer satisfaction ensures that you receive the best possible solutions for your surface treatment needs.

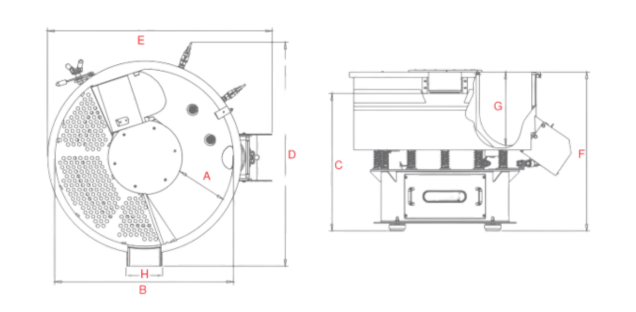

| Machine Type | Chamber Width A | Total Width B | Unload Height C | Total Length D | Total Width E | Total Height F | Chamber Depth G | Unload Width H | Capacity L | PU Thickness | Steel Thickness | Weight Kg | Motor Cycle rpm | Motor Power kW |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| VRX125 | 202.5 | 790 | 840 | 1135 | 1160 | 970 | 328 | 215 | 118 | 20 | 5 | 350 | 1500 | 1.1 |

| VRX225 | 250 | 970 | 935 | 1310 | 1210 | 1080 | 430 | 250 | 228 | 20 | 5 | 465 | 1500 | 1.1 |

| VRX350 | 300 | 1130 | 1005 | 1470 | 1330 | 1155 | 425 | 300 | 309 | 20 | 5 | 600 | 1500 | 2.2 |

| VRX500 | 375 | 1365 | 1030 | 1720 | 1550 | 1200 | 520 | 380 | 570 | 20 | 5 | 790 | 1500 | 4 |

| VRX800 | 430 | 1520 | 1125 | 1805 | 1685 | 1295 | 580 | 380 | 836 | 20 | 6 | 1310 | 1500 | 11 |

| VRX1100 | 480 | 1640 | 1275 | 1910 | 1815 | 1470 | 665 | 420 | 1120 | 20 | 8 | 1550 | 1500 | 11 |

| VRX1500 | 550 | 1790 | 1300 | 2145 | 2010 | 1510 | 668 | 460 | 1396 | 20 | 8 | 2140 | 1500 | 15 |

| VRM2000 | 625 | 1975 | - | 2190 | 2182 | 1585 | 683 | - | 1700 | 20-30 | 10 | 2620 | 1500 | 15 |

| VM3200 | 834 | 2325 | - | 2520 | 2470 | 1510 | 610 | - | 2400 | 25-35 | 10 | 2900 | 1500 | 22 |

| VRX500 | |

|---|---|

| Amplitude | 4 |

| Working Angle | 60 |

| Cycle Time (sec.) | 28 |

| Tumbles per Cycle (pcs.) | 4 |

| Motor (kW) | 4 |

| Motor Speed (rpm) | 1500 |

Watch our video on our vibratory finishing machine with component separation below

Watch our video on vibratory finishing machine noise covers!

Sharmic: Your Partner in Surface Finishing Excellence

Contact us today to discuss how our vibratory finishing machines can revolutionise your surface finishing capabilities.