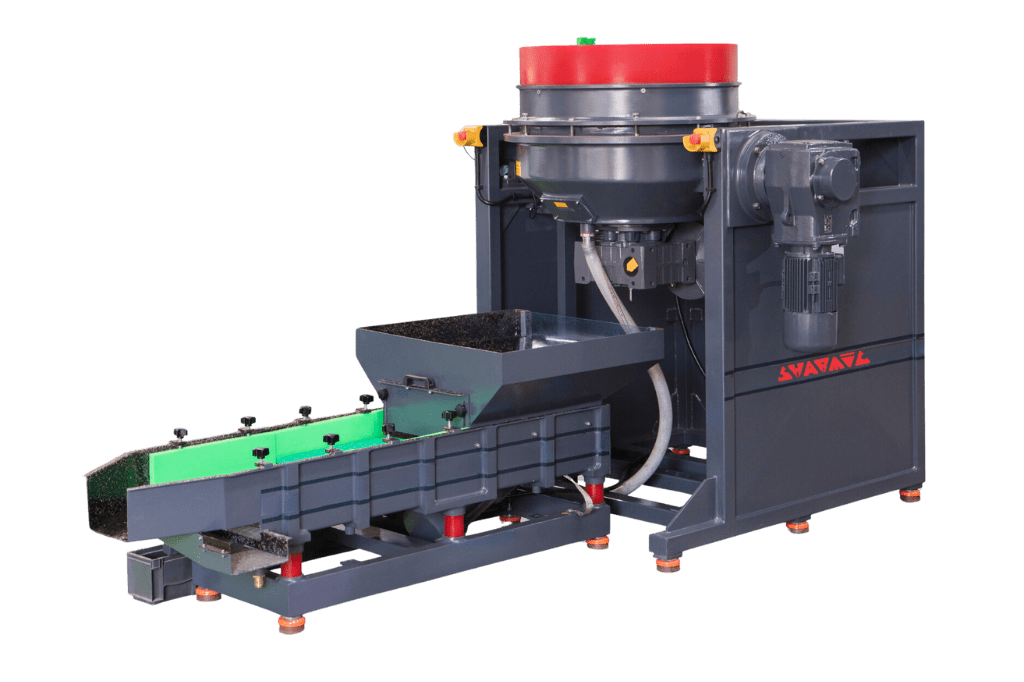

Centrifugal Disc Finishing Machines

Our SM Series Centrifugal Surface Finishing machines are crafted for superior small-parts processing. Utilising centrifugal force, these machines surpass traditional methods, offering faster, precise results. Ideal for deburring and radiusing, the process involves rapid media rotation, enhancing efficiency. With speed control up to 300 RPM, the SM Series is versatile, with the SM14 range especially favoured in the jewellery industry.

Experience unparalleled abrasion and polishing

The SM Series machines are engineered to tackle the most demanding abrasion and polishing applications, achieving results that surpass the capabilities of vibratory processes. Whether you require a high-gloss finish, precise radiusing, our machines seamlessly adapt to your specific needs.

Ergonomic design for effortless operation

Our commitment to user-friendliness extends to the SM Series machines’ low and ergonomic design. The easily observable process area and intuitive controls ensure a seamless and efficient operation, while the manual or automation tilting systems and effortless evacuation process streamline your workflow.

Streamlined process for enhanced productivity

The SM Series machines feature a unique rotary base process chamber and fixed chamber walls. After each cycle, the entire chamber tilts to an angle of 140 degrees, effortlessly transferring the processed material to the VE series vibratory separator (optional extra). This innovative design eliminates cumbersome manual handling, maximising productivity and minimising downtime.

Elevate your surface finishing capabilities

With Sharmic’s SM Series Centrifugal Surface Finishing machines, you gain access to a

revolutionary technology that elevates your surface finishing capabilities to new heights. Experience unmatched abrasion and polishing performance, enhanced productivity, and unwavering user-friendliness. Partner with Sharmic’s today and unlock the true potential of centrifugal surface finishing.

| Machine Type | SM7 | SM14 | SM14 (twin) | SM14 (treble) | SM20 | SM50 | SM100 | SM200 |

|---|---|---|---|---|---|---|---|---|

| Capacity (L) | 7 | 14 | 2 x 14 | 3 x 14 | 20 | 50 | 100 | 200 |

| Polyurethane Thickness (mm) | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

| Process Area Width (mm) | 210 | 280 | 2 x 280 | 3 x 280 | 300 | 425 | 585 | 720 |

| Length (mm) | 605 | 665 | 665 | 665 | 745 | 1105 | 1350 | 1700 |

| Width (mm) | 425 | 465 | 930 | 1395 | 525 | 950 | 1380 | 1655 |

| Height (mm) | 1210 | 1260 | 1260 | 1260 | 1310 | 1530 | 1460 | 1935 |

| Weight (kg) | 65 | 100 | 200 | 300 | 100 | 303 | 790 | 970 |

| Motor Power (kW) | 0,37 | 1,1 | 2 x 1,1 | 3 x 1,1 | 0,75 | 3 | 4 | 10 |

Sharmic: Your Partner in Surface Finishing Excellence

If you are looking for a fast, efficient, and versatile way to surface treat metal and plastic items, then a tilting rotary barrel system is the perfect solution for you.